rev 5/1/25

Chloroform production and use

Main properties

Molecular Formula CHCl3

Molecular Weight 119.37 g/molOdor Pleasant, etheric, nonirritating

Boiling Point 61.12 °C

Melting Point -82.3 °F -63.47 °C

Density (at 20 °C): 1.48 g/ml

Synonyms

67-66-3 Chloroform Chloroforme (French)

Formyl trichloride Methane trichloride Methenyl chloride

Methenyl trichloride Methyl trichloride NCI-C02686

Pure chloroform is light sensitive and reagent grade chloroform usually contains 0.75% ethanol as stabilizer

CHLOROFORM PRODUCTION

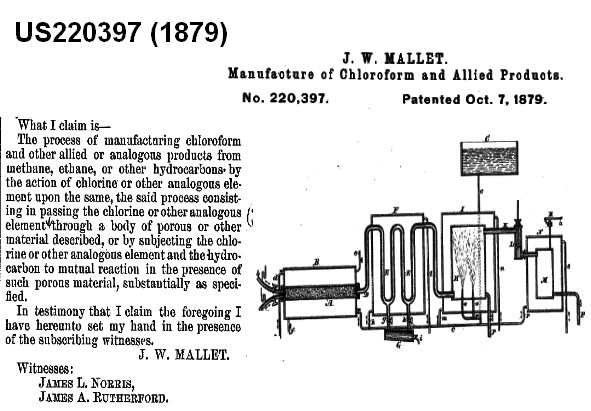

Chlorination

of methane is well known with many patents taken by various

corporations since 1879 .The reaction which very exothermic is done in continuous

and give a mixture of diffferents chloroalcanes CHCl3,

CH2Cl2,CHCl3,CCl4.....which are separated by distillation .The reaction

is carried out between 200 et 500° c under pressure with short reaction

time (in the second range) .

The

reaction can also be done in liquid phase with the help of UV light

(Photochlorination) .In this case conditions are generally milder e.g. temp

50°c pressure few bars.

It is also possible to

get chloroform by dechloration of carbon tetrachloride as

mentioned in patent

EP0460138B1 Published 1995-02-15

As the market of chloroalacanes is changing over the time the processes have to be flexible to fit production to the market

Here are some examples taken from a very rich patent litterature .More details here

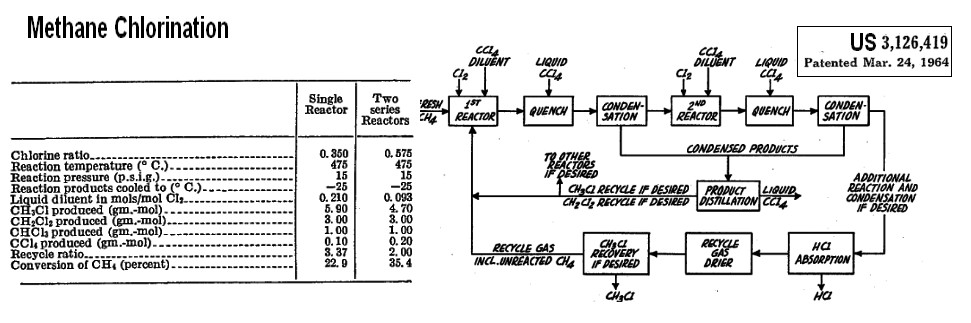

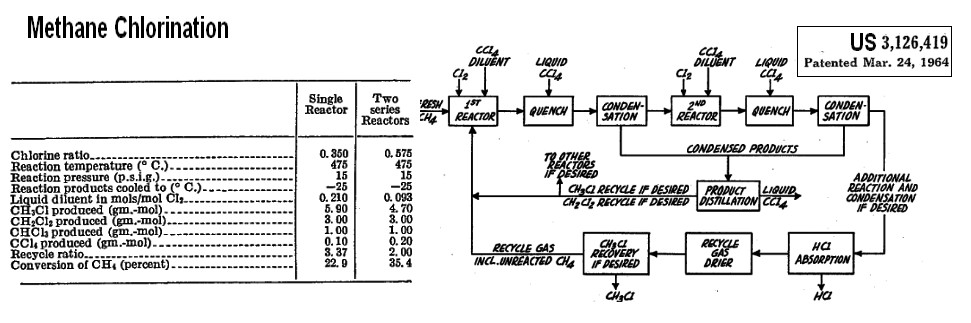

Vapor Chlorination of methane

US 3,126,419 CHLORINATION OF METHANE assignors to Stauffer Chemical Filed Sept. 26, 1960, Ser. No. 58,367

This

invention relates in general to a process for the partial chlorination

of methane and in particular to a process for maximum production of

methylene chloride

and/or to chloroform via the chlorination of methane.

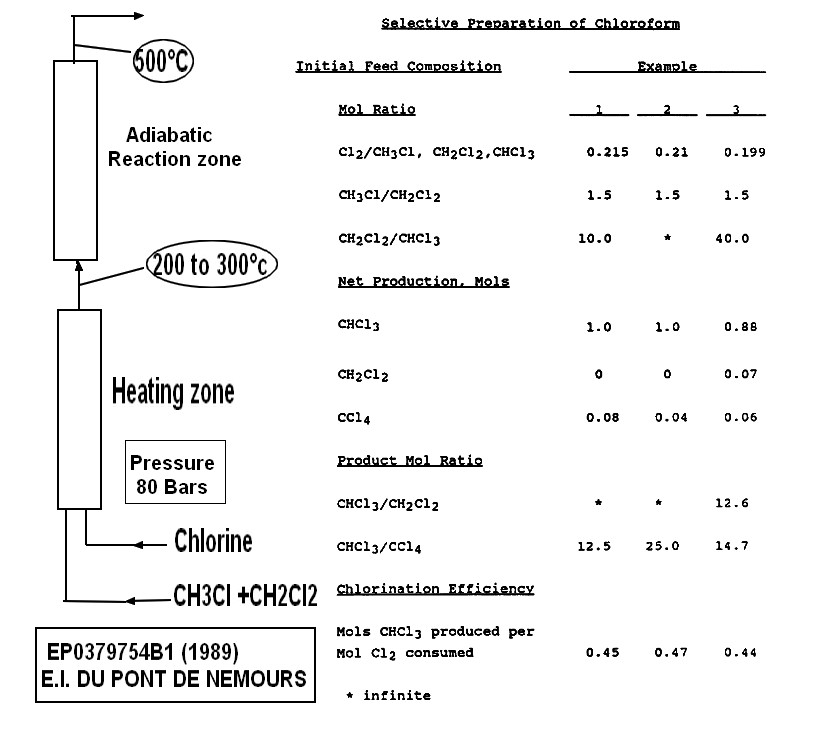

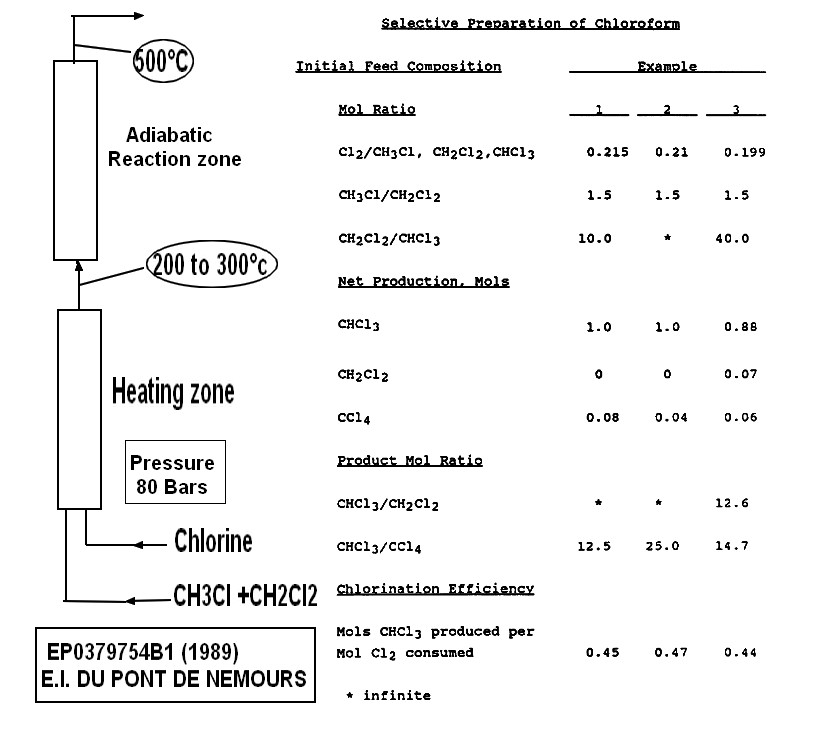

Chlorination of methyl chloride/methylene dichloride

EP0379754B1 E.I. Du Pont De Nemours Priority

1987-11-10 • Filed 1989-01-24 • Granted 1994-03-23 • Published

1994-03-23

The

chlorinated methanes (methyl chloride, methylene chloride, chloroform

and carbon tetrachloride) are well-known articles of commerce and are

generally prepared by chlorination of an underchlorinated raw material.

As the demand for the individual members of the series varies from time

to time, it is desirable to be able to control their production

accordingly.

At present (1987) the demand for chloroform

is high, that for methylene chloride and carbon tetrachloride is low.

The existing chlorination processes, however, are not entirely

satisfactory for producing chloroform to the substantial exclusion of

the other polychloromethanes. For example, the direct chlorination of

methane for this purpose (described in SRI #126, C₁ Chlorinated

Hydrocarbons, published August 1978, pages 49 to 96) is difficult to

control and expensive to operate because of the necessity of recycling

large amounts of methane, methyl chloride and methylene chloride. It

also tends to produce undesirably high ratios of carbon tetrachloride

to chloroform, which constitutes a cost penalty in view of the

relatively low demand for the tetrachloride.

The production of

methyl chloride is readily controlled by utilizing the reaction of

hydrogen chloride with methanol, and for this reason it is an

attractive starting material for the higher chlorinated methanes.

CH3Cl + CH2Cl2 + Cl2 -------> CHCl3 +CCl4 Pressure 80 bars temp 200 to 500°c

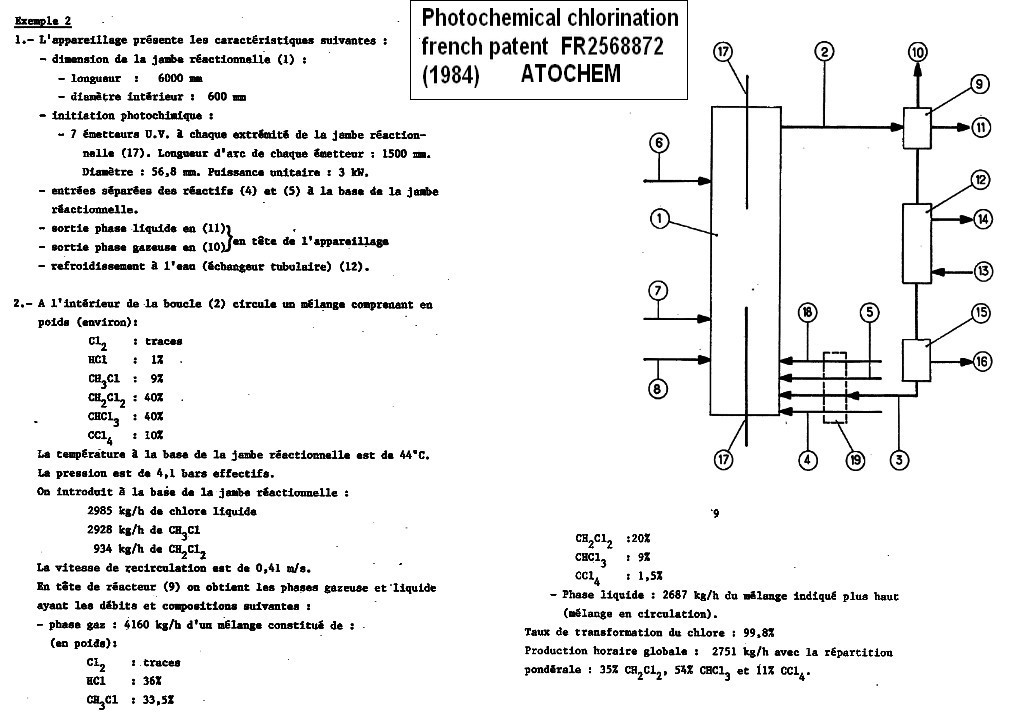

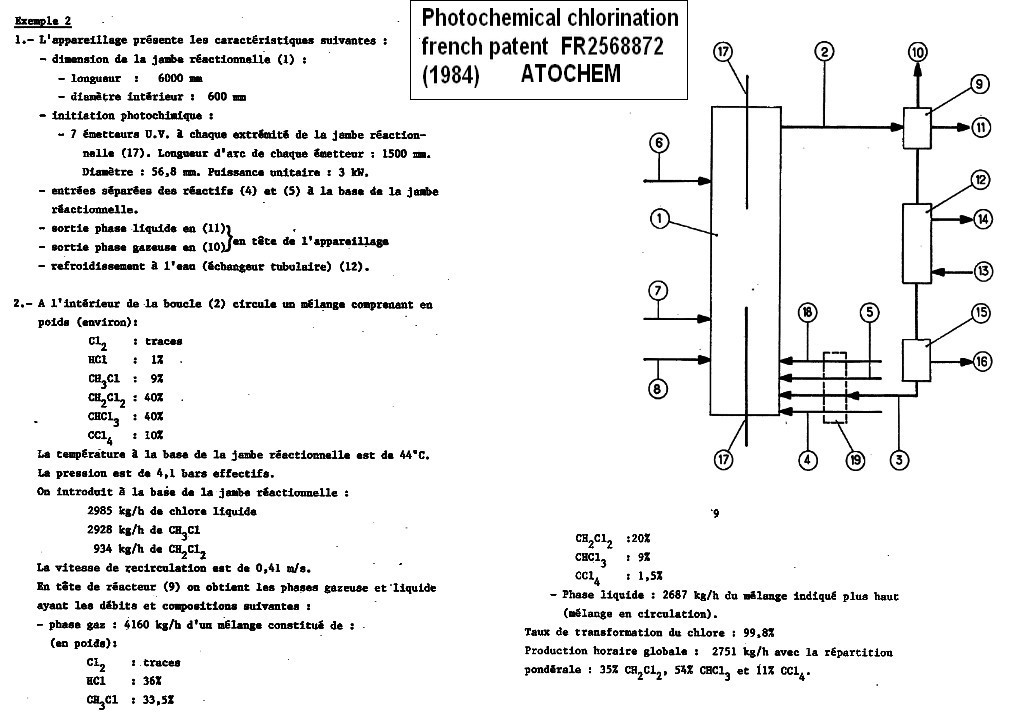

PhotoChlorination of methyl chloride/methylene dichloride

FR2568872B1 * 1984-04-27 1986-11-28

Atochem CONTINUOUS PROCESS OF RADICAL CHLORINATION OF

CHLOROALKANES

The chlorination of a mixture of methyl

chloride/methylen chloride can be done by activation of chlorine with

UV lamps (photochlorination) in liquid phase .In this case typical

working condition are : temperature 44°c , pressure 4 bars

.Chloroform is the main product with small amounts de CCl4

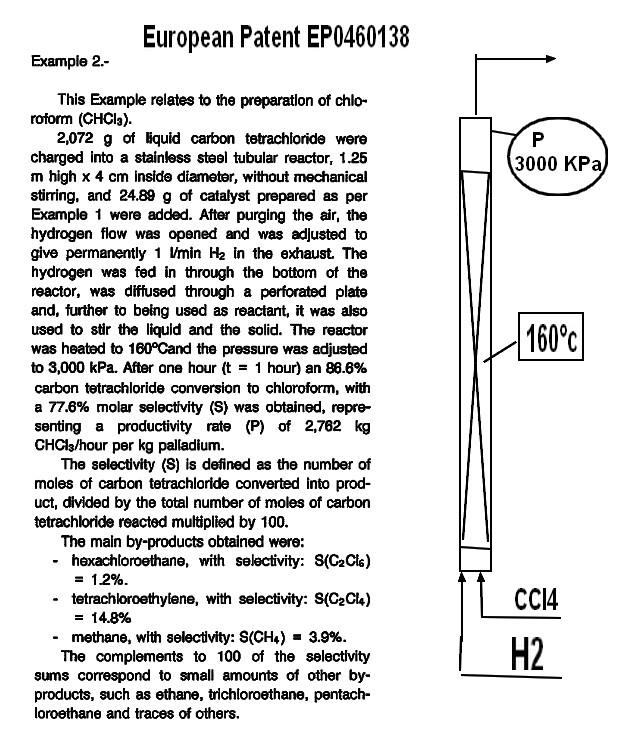

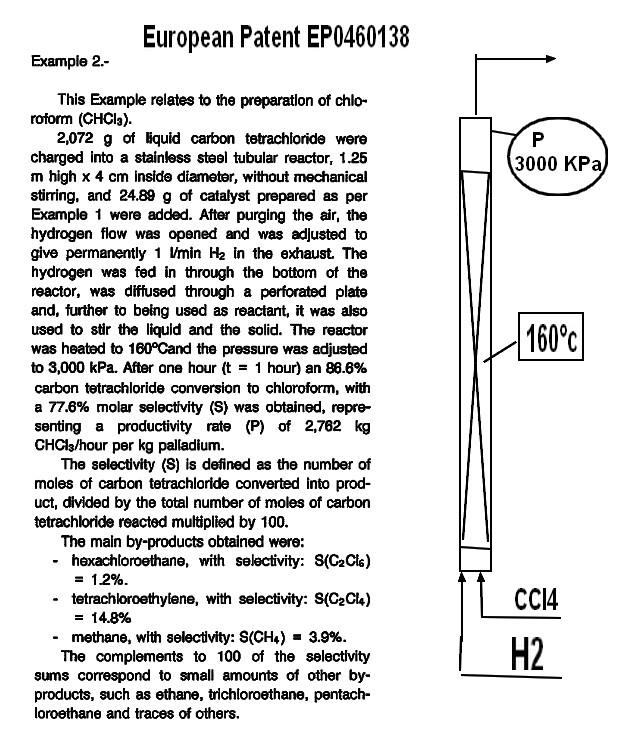

CHCl3 by catalytical hydrogenation of CCl4

EP0460138 Priority 1989-12-22 • Filed 1990-12-13 • Granted 1995-02-15 • Published 1995-02-15

CCl4 + H2 ------> CHCl3 + HCl

Catalyst Pd/Carbon temp 160°C pressure 3000 KPa

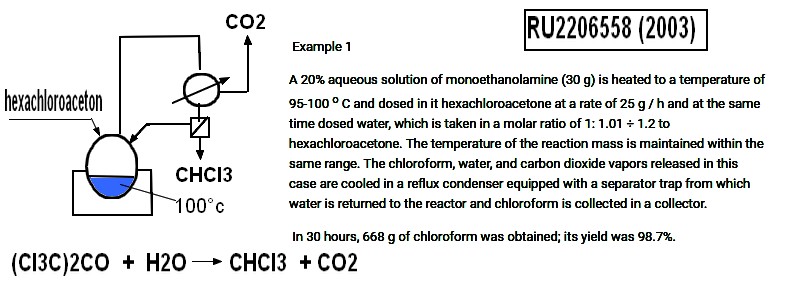

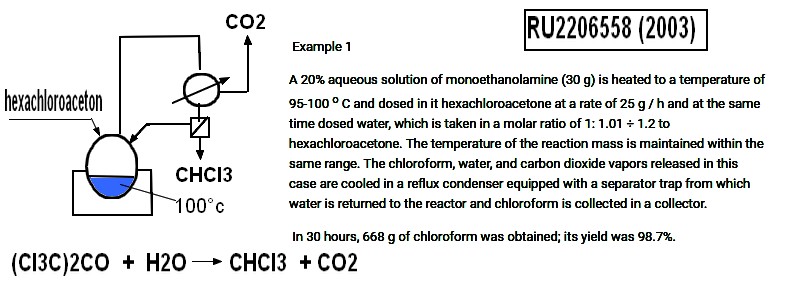

CHCl3 from hexachloroacetone

Russia Patent RU2206558C1 2003-06-20 Publication of RU2206558C1

The

method of producing chloroform by hydrolysis of hexachloroacetone at

elevated temperature, characterized in that hexachloroacetone is

hydrolyzed with water in the presence of ethanolamines as a catalyst at

95-150 o With simultaneous distillation of the reaction product -

chloroform.

Hexachloroacetone

can be obtained by action of chlorine on ispropanol or better from

acetone in very good yield (>95%) , catalysis by pyridine as depicted in China patent

CN109942392A (2022-01-21)

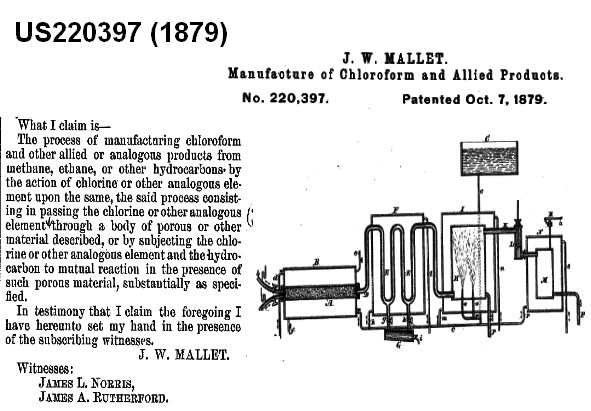

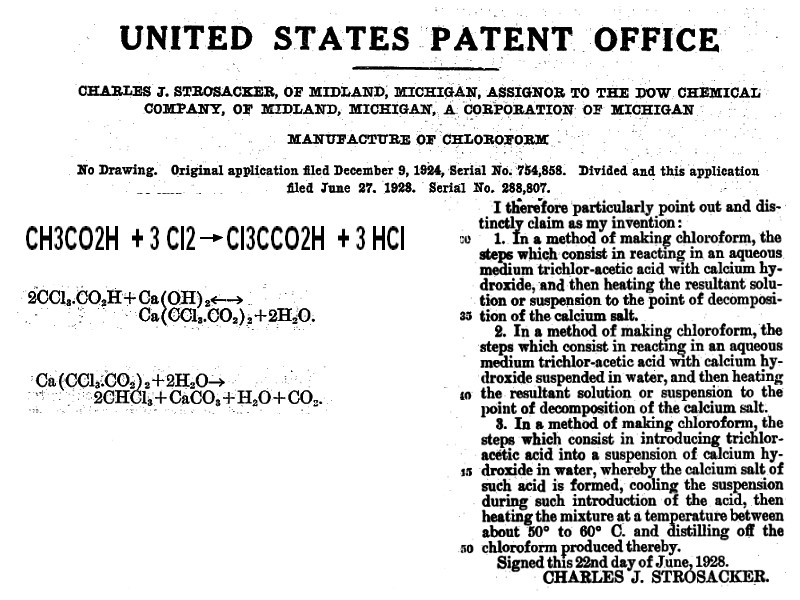

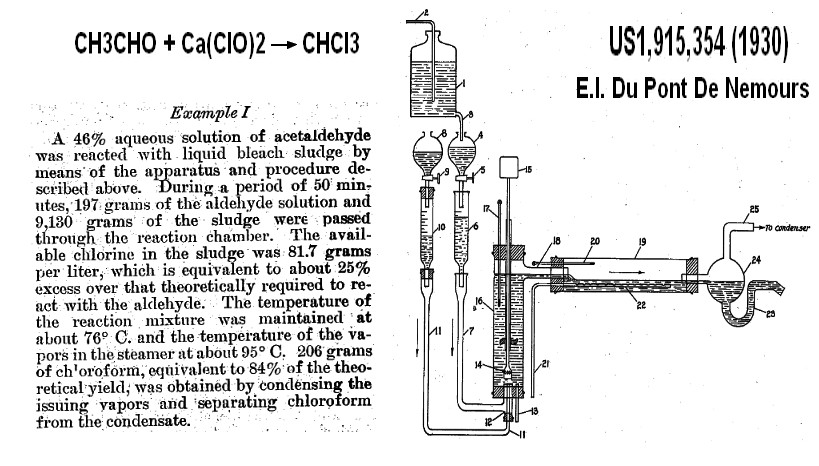

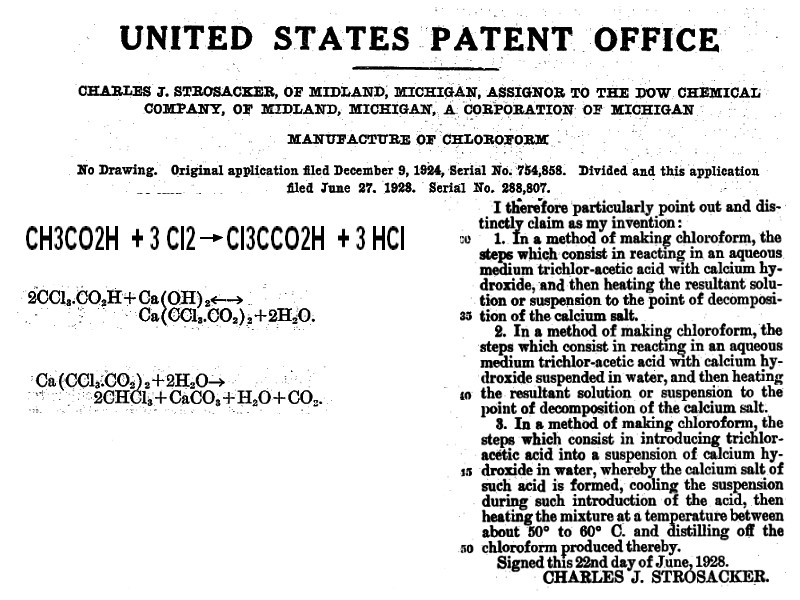

Vintage processes

Chlorination of methane (1879)

decarboxylation trichloroacetic Calcium salt(1928)

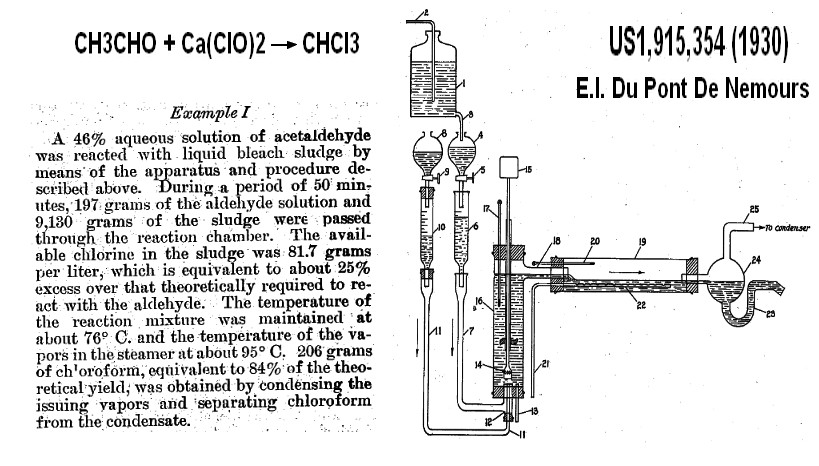

Chlorination of carbonyl product

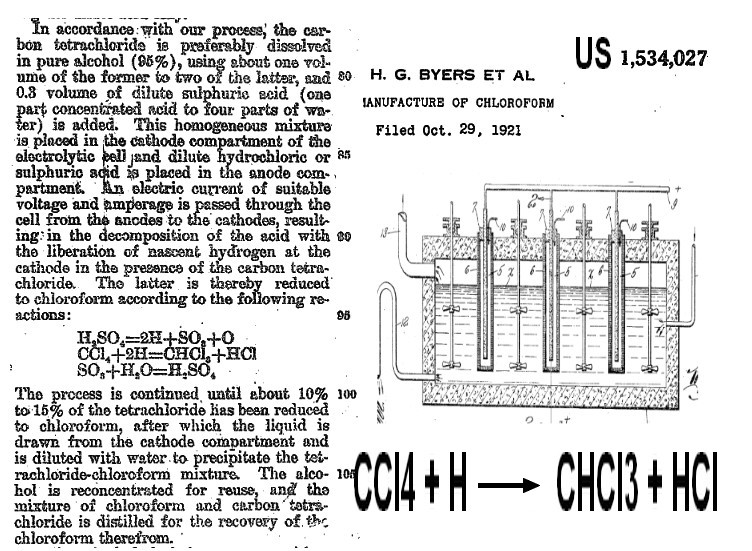

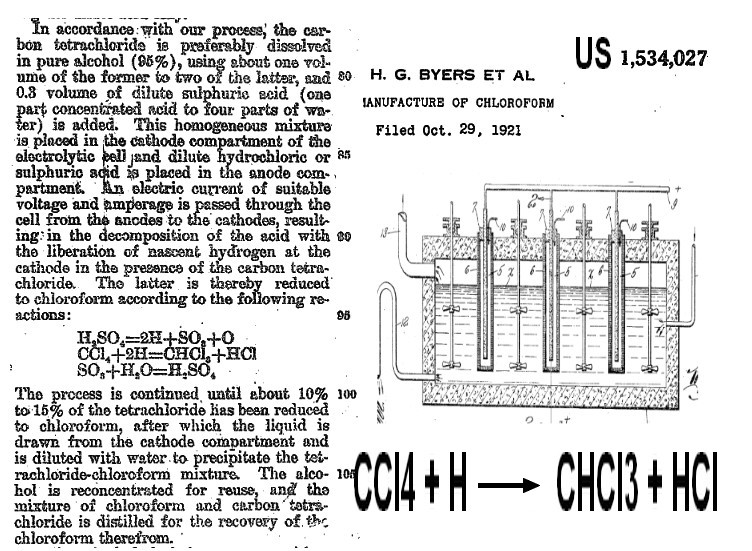

Electro Reduction of CCl4

Elctroreduction of carbone tetra chloride in mixture CCl4/EtOH/H2SO4 (US1534027 (1921)

Chemical reduction of CCl4

US2104703A Dow Chemical Co Priority 1936-02-13 • Filed 1936-02-13 • Granted 1938-01-04 • Published 1938-01-04

Patented

Jan. 4, 1938 UNHTED S'E'AS Arm FFlE METHOD FOR. THE MANUFACTURE OF

CHLOROFORM No Drawing. Application February 13, 1936, Serial No. 63,734

9 Claims. This invention concerns an improved method of manufacturing

chloroform by reaction of carbon tetrachloride with iron and water.

2CCl4 + 2H2O + 2 Fe --->FeCl2 + Fe(OH)2 + 2CHCl3

Reaction catalysed by various Pb salt

CHLOROFORM USAGE

In terms of scale, the most important use of chloroform is to give monochlorodifluoromethane (HCFC-22 alias R-22),

CHCl3 + 2 HF → CHClF2 + 2 HCl

The reaction is conducted in the presence of a catalytical amount of mixed antimony halides.

Chlorodifluoromethane

, a colorless gas is better known as HCFC-22, or R-22, or CHClF2. It

was commonly used as a propellant and refrigerant. These applications

were phased out under the Montreal Protocol in developed countries in

2020 due to the compound's ozone depletion potential (ODP) and high

global warming potential (GWP), and in developing countries this

process will be completed by 2030.

R-22 still remain a

versatile intermediate in industrial organofluorine chemistry, e.g. as

a precursor to tetrafluoroethylene by pyrolysis (at 550–750 °C) ,

with difluorocarbene as an intermediate.

2 CHClF2 → C2F4 + 2 HCl

Polymerization

of tetrafluoroethylene produces polytetrafluoroethylene (PTFE) polymers

such as Teflon , Fluon and many others

Worldwide,

chloroform is also used in pesticide formulations, as a solvent for

lipids, rubber, alkaloids, waxes, gutta-percha, and resins, as a

cleaning agent, as a grain fumigant, in fire extinguishers, and in the

rubber industry.