Preparation of formaldehyde

Abstract

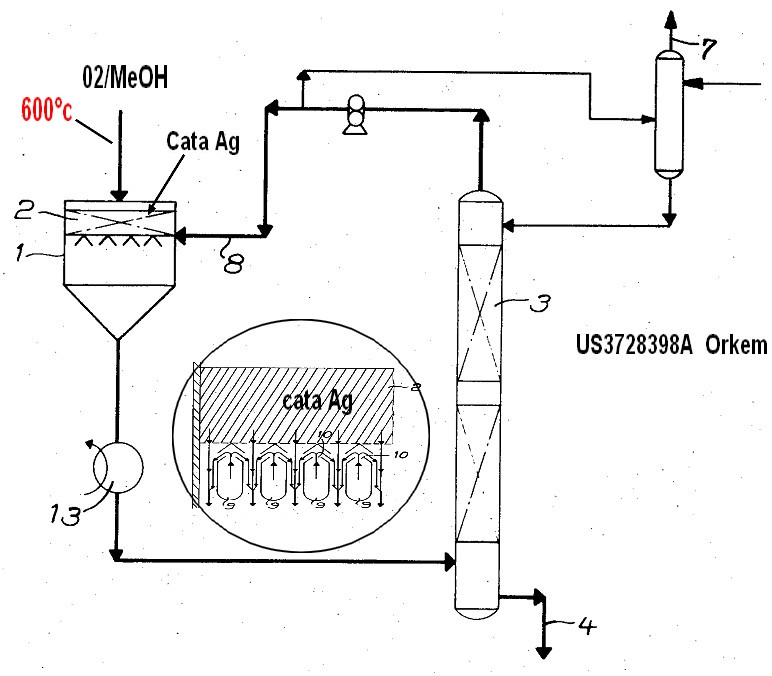

This invention relates to an improved process for the preparation of formaldehyde by oxidising methanol by air in the presence of a silver catalyst and is characterised in that the gases leaving the installation after separation of the condensable products, viz. water, methanol and formaldehyde, are at least partly reinjected in the cold state into the gaseous mixture leaving the catalyst layer. The present invention relates to the preparation of formaldehyde by the known process of oxidising methanol by air in the presence of a silver catalyst. In this known preparation, a gaseous mixture of methanol and air is passed at a suitable temperature over a silver catalyst. The reaction products leave the catalyst layer at a temperature between approximately 500*C and 650*C. These gases also contain the methanol which has not reacted, as well as the desired formaldehyde, water, nitorgen, carbon monoxide, carbon dioxide and hydrogen. It was proved nitrogen, long time ago that in such a gaseous mixture, the temperature of which is between approximately 500*C and 600*C, a certain number of chemical reactions are liable to develop which are considered as parasitic with respect to the main formation reaction of the formaldehyde and which it is generally desired to minimise or suppress. To this end, various methods have been advocated which can be summed up more particularly in the use of an indirect heat exchanger and in the use of atomization of water or a diluted solution of formol. Naturally, it was the aim of the various known methods to lower the temperature of the gases leaving the catalyst layer as quickly as possible to a value lower than 350*C - 450*C. These methods of treating hot gases have various drawbacks and it is an object of the invention to avoid or minimise these drawbacks as far as possible. According to the present invention, a method of preparing formaldehyde by oxidising methanol by air in the presence of a silver catalyst is characterised in that the gases leaving the plant after separation from the condensable products (water, methanol and formaldehyde) ARE AT LEAST partly reinjected in the cold state into the gaseous mixture leaving the catalyst layer. The reinjected gases contain, more particularly, nitrogen, carbon dioxide, carbon monoxide and hydrogen. These gases are referred to as ''''tail'''' gases, and are cold, since they are obtained after treating the gaseous mixture leaving the catalyst layer by known methods having as an object, the condensation or absorption of the condensable chemical products contained in this gaseous mixture. They are, on the other hand, only of small value and are usually rejected to atmosphere. However, used according to the invention, they allow the yield from a plant for preparing the formaldehyde to be substantially improved. This improvement in the yield is carried out following a complex mechanism which has not yet been entirely elucidated. It is caused certainly partly by the rapid cooling of the gaseous mixture leaving the catalyst layer, in which the synthesis of the formal dehyde is carried out: for this reason, it will be apparent that the reinjection of the tail gases must be effected as near as possible to the last layer of the catalyst bed and that it must be ensured, if maximum improvement is to be obtained, that a good distribution of the gases injected into the gaseous mixture leaving the catalyst is effected. But it is also certain that the improvement of yield is caused partly by the composition of the said tail gas. In order to obtain maximum improvement of yield, it has been found, on the other hand, that it was necessary to inject a quantity of tail gas into the gaseous mixture leaving the catalyst layer, representing per molecule of formol (formaldehyde) prepared approximately 1.7 times the quantity of tail gases produced. This is why, according to the invention, such a quantity of tail gas will be made to circulate and be reinjected into the gaseous mixture and that the gaseous circuit will be cleared from the excess gases produced as the reaction takes place. Amongst the other advantages of the method according to the invention may be mentioned: 1. The increase in the volume of inert gas resulting from the recirculation enables the evaporation of a large part of the water and methanol situated at the base of the first absorption tower, which is a particularly interesting advantage when ureaformaldehyde concentrates are to be produced by absorption by means of solutions of urea. 2. This same increase of the gaseous volume leaving the reactor facilitates thermal recuperation of the reaction heat by exchange, whilst avoiding premature condensation in the exchangers, on account of the partial decrease in pressure of the condensable part. 3. The invention can be adapted immediately to methods using a circuit operating at a pressure lower than atmospheric pressure throughout the line with synthesis of transport for the gases situated at the tail of the installation. Only the calibre of the compressor or ventilator used is to be increased.

Patent Citations (1)

Cited By (4)

Similar Documents

Priority And Related Applications

***************************************************************

Priority 1984-04-12 • Filed 1984-04-12 • Published 1994-08-17

Claims (1)

In the method for producing a 0% by weight formaldehyde solution, the amount of air per mol of the raw material methanol is 1.5 to

The total amount of water was 2.0 mol and the amount of water corresponding to the amount of water vapor added to the raw material gas and the amount of water necessary to dilute the product formaldehyde solution was added as absorption water from the top of the absorption tower,

In addition, the methanol concentration is 0.1 to 3.0 from the upper stage of the absorption tower.

Wt%, formaldehyde concentration of 0.1-1.0 wt% aqueous solution of the composition of 0.2 ~ per mol of the starting methanol

A method for producing an aqueous formaldehyde solution, which comprises extracting as a 0.8 mol side stream, adding this to a raw material gas, and reacting at a temperature of 580 to 680 ° C.

Description

translated from Japanese

DETAILED DESCRIPTION OF THE INVENTION 1) Field of Industrial Application The present invention relates to a method for producing a formaldehyde aqueous solution having a low methanol content by catalytically reacting a raw material gas containing methanol, air and water on a silver catalyst.

2) Conventional technology As a method for producing formaldehyde by oxidative dehydrogenation of methanol, a raw material methanol and air were further obtained by reacting a raw material gas obtained by adding steam and waste gas if necessary on a silver catalyst. It is common to recover the reaction heat from the reaction gas with a boiler, if necessary, and then introduce it into a water absorption tower to recover formaldehyde as an aqueous solution. In this case, since methanol is used in excess of air, unreacted residual methanol is generally mixed in the obtained formaldehyde. The residual methanol itself contributes to the stabilizing effect of the formaldehyde solution, but the excessive presence of methanol is wasteful, and in recent years, it has been required to produce an aqueous formaldehyde solution having a low methanol content.

Therefore, usually, a method is employed in which the amount of residual methanol in the reaction product gas is reduced by increasing the air / methanol molar ratio to about 1.8 to obtain formaldehyde having a low methanol content. In this case, avoid the explosion range and suppress the reaction temperature. Therefore, although steam is usually added to the raw material gas, this steam remains in the reaction product gas and is condensed in the absorption tower to reduce the concentration of the product formaldehyde aqueous solution. Therefore, the concentration of the formaldehyde aqueous solution produced by this method is limited to about 45% by weight.

On the other hand, as an effective means for reducing the methanol content of the product formaldehyde aqueous solution and increasing the formaldehyde concentration, there is a so-called waste gas circulation method in which a part of the absorption tower waste gas is added to the raw material gas. Is also a practically feasible product The concentration of formaldehyde aqueous solution is 55

Up to about wt%.

Further, when the air / methanol ratio of the raw material gas is increased, the combustion reaction of methanol and other side reactions tend to proceed and the formaldehyde selectivity tends to be lowered. Therefore, it is preferable to make the air / methanol ratio as low as possible.

3) Problems to be Solved by the Invention In order to solve the above-mentioned drawbacks, the present invention has an air / methanol molar ratio of the raw material gas of 1.5 to 1 when adding only steam to the raw material gas. About 6 or about 1.6 to 1.8 when waste gas is added to the raw material gas, and a formaldehyde aqueous solution having a low methanol content and a high formaldehyde concentration while reacting under milder conditions than conventional methods. To provide a method of manufacturing.

4) Means for solving the problem That is, in the present invention, a raw material gas containing methanol, air and steam is subjected to a catalytic reaction on a silver catalyst, and the obtained reaction product gas is contacted with water to remove formaldehyde in the product gas. Absorb in water, formaldehyde concentration 37 ~ 6 from the bottom of the absorption tower

In a method for producing a 0% by weight formaldehyde solution, water in an amount corresponding to water vapor added to a raw material gas,

Add the total amount of water necessary for diluting the product formaldehyde solution from the top of the absorption tower as absorbed water, and from the upper stage of the absorption tower, methanol concentration 0.1-3.0% by weight, formaldehyde concentration 0.1-. This is a method of producing formaldehyde by extracting an aqueous solution having a composition of 1.0% by weight as a side stream in an amount corresponding to water vapor added to a raw material gas, adding this to the raw material gas and reacting them.

5) Operation The raw material gas in the present invention contains methanol, air and water vapor, and if necessary, an inert gas such as a waste gas after the recovery of formaldehyde can be added to the reaction.

The composition of the source gas is methanol 1 if no waste gas is added.

Empty 1.5-2.0 mol per mol, preferably 1.6-

It is 1.8 moles, steam is 0.2 to 0.8 moles, and preferably 0.4 to 0.6 moles. When a waste gas is added, the empty space is 1.6 to 2.2 mol, preferably 1.8 to 2.0 mol, and water vapor is 0.2 to 0.6 mol, preferably 0.2 to 0. 5 mol, waste gas 0.2 to 2.0 mol, preferably 0.4 to 1.5 mol.

A raw material gas having such a composition is introduced onto an ordinary catalyst for producing formaldehyde such as electrolytic silver, and the temperature is 580 to 680 ° C., preferably 620 to 650 ° C., and the linear velocity is 0.8 to 2.0 m / se.

c, preferably 1.0 to 1.5 m / sec.

The reaction product gas obtained was formaldehyde 15-25.

%, Temperature 580-6 containing 0.2-2.0% methanol

It is a high temperature gas of 80 ° C., and therefore, it is usually passed through a multi-tube boiler installed directly below the reactor to obtain a temperature of 120-

After cooling to 160 ° C, it is introduced into an absorption tower.

The absorption tower is divided into three parts, the upper part, the middle part and the lower part, and the upper part is the plate tower, the middle part and the lower part are the packed towers. Water is supplied from the top of the tower and formaldehyde in the reaction product gas introduced from the bottom of the tower is absorbed. In the packed towers in the middle and lower parts of the tower, the absorbed water is withdrawn from the bottom of the tower to the outside as a side stream, cooled, and then circulated again to the top of each tower. Due to such external cooling, the temperature of the lower packed tower is 60 to 80 ° C, and the temperature of the middle packed tower is 20 to 30 ° C.

Kept at ℃. As a result, most of the formaldehyde and part of the methanol are absorbed and condensed in the lower packed column, and almost all of the formaldehyde and half of the tanol are absorbed in the middle packed column.

From the top of the upper tray tower, which is the top layer of the absorption tower, the amount of water necessary for diluting the aqueous formaldehyde solution that is withdrawn from the bottom of the tower as a product is usually introduced as absorbed water. 600-2000 ppm formaldehyde in the overhead gas released, 1

500-5000ppm methanol and methyl formate 7

A loss of 0.00 to 3000 ppm is included. In the present invention, in addition to the amount of water necessary for diluting the product formaldehyde aqueous solution from the top of the plate tower, water is added in an amount corresponding to the water added to the raw material gas, and the upper plate column (total plate number 10 to 10). 25 stages) in the middle part (5 to 20 stages from the top of the column), where the concentration of methanol is 0.1 to 3.0 wt% and the concentration of formaldehyde is 0.1 to 1.0 wt% An amount equivalent to the amount of water to be added is withdrawn as a sidestream, and this is added to the raw material gas and reacted. Therefore, the amount of water added from the top of the absorption tower is 2 to 5 times that of the usual method, and accordingly, the content of formaldehyde, methanol, methyl formate, etc. in the waste gas discharged from the top of the absorption tower is remarkable. Decrease. Further, the side stream extracted from the upper tray column contains 1 to 4 times, especially 2 to 3 times by weight, methanol of formaldehyde, and the addition of this to the raw material gas improves the methanol unit consumption. And methanol is extracted as a sidestream, the amount of methanol mixed in the product formaldehyde aqueous solution is reduced, and it is possible to obtain a formaldehyde solution having a low methanol content despite the reaction under methanol-rich reaction conditions. .

The product formaldehyde solution obtained by the present invention has a formaldehyde concentration of 37 to 60% by weight, preferably 45 to

60 wt%, methanol concentration 0.5-3.0 wt%, preferably 0.5-1.0 wt%, the amount of formic acid by-produced at this time is 100 wtppm or less, usually about 50-60 wtppm Is. The water extracted as a sidestream is heated to 60 to 80 ° C. by a heat exchanger and is contacted with the raw material air to evaporate to form a raw material gas.

6) Effect of the Invention According to the present invention, the amount of absorbed water introduced from the top of the absorption tower is larger than that in the usual method, so that unabsorbed components in the waste gas are reduced,

Not only can the unit consumption of methanol be improved by that much, but it is also possible to react under mild reaction conditions by adopting methanol-rich reaction conditions on the premise of recovery of residual methanol. This also leads to the advantage that the amount of water vapor to be mixed can be reduced, and the effect is extremely large.

7) Example Example-1 In FIG. 1, 2410 kg / hr of methanol was introduced into 1 from FIG. Also from 3 air 3050 Nm 3 / hr

Is introduced into the humidifier 4 and extracted from 5 and the heat exchanger 6

Countercurrent contact with 600 kg / hr of flowing water on the absorption tower side heated to ℃. The sidestream water contained 2% by weight of methanol. Humidified water is extracted from the bottom of the tower, and the temperature is 65 ° C and 80%.

It was circulated at a flow rate of m 3 / hr. Air temperature at the humidifier outlet is 63

C., and the amount of humidification is adjusted by keeping this temperature constant. The heated methanol vapor and air are mixed and further enter reactor 8 with the waste gas from 7. The molar ratio of methanol: air: steam: waste gas at the reactor inlet is 1: 1.8: 0.4: 1.3. A silver catalyst is held in the reactor and reacted at a reaction temperature of 620 ° C. to form formaldehyde. The reaction product gas exchanges heat with pressurized water by a waste heat boiler attached to the lower part of the reactor and is cooled to 120 ° C, then enters the bottom of the series column lower packed column 9 and countercurrently flows with circulating water at 60 ° C of 10 140 m 3 / hr. Contact. Most of the formaldehyde and part of the methanol are absorbed here, and the residual gas is further circulated in the middle packed column 11 at a temperature of 30 ° C 12 140 m 3

In countercurrent contact with / hr, almost all of formaldehyde is absorbed. Further, the unabsorbed gas is led to the upper tray tower 13,

In countercurrent contact with 700 kg / hr of absorbed water having a temperature of 20 ° C. introduced from the top, methanol and formaldehyde are completely absorbed. The input gas extracted from the top of the tower is formaldehyde 100ppm, methanol 300ppm, methyl formate 400.

It only contained ppm. The product formaldehyde solution was obtained at a rate of 3650 kg / hr from 15, the formaldehyde concentration was 55% by weight, and the methanol concentration was 1.

It was 0% by weight and formic acid content was 50 ppm by weight.

Example-2 As shown in FIG. 2, the waste gas 7 was introduced into the humidifier 4 together with air to increase the amount of humidification. The composition of the raw material gas obtained as a result is methanol: air: steam: waste gas = 1: 1.8: 0.6:

1.3.

The reactor temperature was maintained at 610 ° C. The operating conditions of the absorption tower are almost the same as in Example 1, but the amount of absorbed water from the top of the absorption tower is 1000 kg / hr, and the side-stream withdrawal amount is 900 kg.

/ Hr. The product formaldehyde solution was obtained at the rate of 3950 kg / hr, the formaldehyde concentration was 51% by weight, the methanol was 0.7% by weight, the formic acid content was 50% by weight, and the waste gas contained 80% formaldehyde and 25% methanol.

It contained 0 ppm and 350 ppm of methyl formate.

Example-3 In FIG. 1, 2250 kg / hr of methanol was introduced into the evaporator 2 from 1 and made into a gaseous state. In addition, air from 3 is 2530 Nm 3 / hr

Is introduced into the humidifier 4 and extracted from 5 and the heat exchanger 6

The countercurrent contact of 900 kg / hr of flowing water on the absorption tower side heated to ℃. This sidestream water contained 1.7% by weight of methanol. The water from the humidifier is withdrawn from the bottom of the tower and the temperature is 65 ° C.

Circulation was carried out at a flow rate of 0 m 3 / hr. Air temperature at the humidifier outlet is 6

It is 2 ° C., and the amount of humidification is adjusted by keeping this temperature constant. The heated methanol vapor and air are mixed and enter the reactor 8 (waste gas is not mixed).

The molar ratio of methanol: air: steam at the reactor inlet is 1: 1.6: 0.7. A silver catalyst is held in the reactor and reacted at a reaction temperature of 620 ° C. to form formaldehyde. The reaction product gas exchanges heat with pressurized water in a waste heat boiler attached to the lower part of the reactor, is cooled to 110 ° C., and then enters the bottom part of the absorption tower lower packed column 9, and the circulating water at 60 ° C. 10 1

Countercurrent contact with 40 m 3 / hr. Most of the formaldehyde and part of the methanol are absorbed here, and the residual gas is countercurrently contacted with the circulating water of 12 140 m 3 / hr at 30 ° C in the middle packed column 11 and almost all of the formaldehyde is absorbed. .

Further, the unabsorbed gas is introduced into the upper tray column 13 and comes into countercurrent contact with 1400 kg / hr of absorbed water having a temperature of 20 ° C. introduced from the top, and methanol and formaldehyde are completely absorbed. The waste gas extracted from the top of the tower is formaldehyde 6

It contained only 0 ppm, 200 ppm methanol, and 300 ppm methyl formate. The product formaldehyde solution was obtained from 15 at a rate of 3890 kg / hr, the formaldehyde concentration was 47.6% by weight, and the methanol concentration was 3.4.

% By weight, and the formic acid content was 50 ppm by weight.

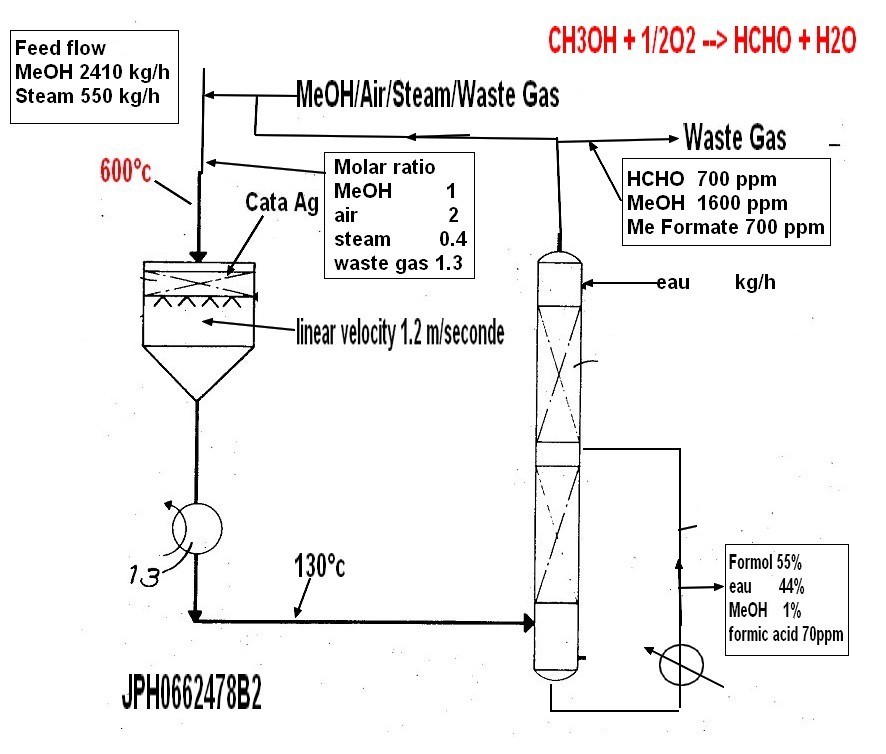

Comparative Example 1 In FIG. 1, there is no side stream 5 and humidifier 4, and the steam added to the raw material gas was mixed with other raw material gas (methanol, air, waste gas) in front of the reactor 8.

That is, 2410 kg / hr of methanol is introduced from 1 into the evaporator 2 and made into a gaseous state. In addition, 3 3 Nm 3 / hr of air was introduced from 3, and the heated methanol vapor and air were mixed,

Add 550 kg / hr of steam. The mixed gas also enters reactor 8 along with waste gas from 7.

The molar ratio of methanol: air: steam: waste gas at the reactor inlet is 1: 2.0: 0.4: 1.3.

A silver catalyst is retained in the reactor and reacts at a reaction rate of 650 ° C to form formaldehyde. The reaction product gas exchanges heat with pressurized water in a waste heat boiler attached to the bottom of the reactor and is cooled to 130 ° C, then enters the bottom of the absorption tower lower packed tower 9

Countercurrent contact with circulating water 10 (140m 3 / hr) at ℃. Most of the formaldehyde and a part of the methanol are absorbed here, and the residual gas is brought into countercurrent contact with the circulating water 12 (140 m 3 / hr) at 30 ° C in the middle packed column 11, and the unabsorbed gas is further absorbed in the upper plate column. Led to 13,

Most of the formaldehyde is absorbed by making countercurrent contact with 100 kg / hr of absorbed water at a temperature of 20 ° C, which is introduced from the top.

The waste gas extracted from the top of the tower is formaldehyde 700

ppm, methanol 1600 ppm, methyl formate 700 ppm. 3610 kg / hr of product formaldehyde solution was obtained, and the product formaldehyde concentration was 55% by weight.

The methanol concentration was 1.0% by weight, and the formic acid content was 70 ppm by weight.

COMPARATIVE EXAMPLE 2 In Comparative Example 1, 3050 Nm 3 / hr of air was introduced from 3 . The molar ratio of methanol: air: steam: waste gas at the reactor inlet is 1: 1.8: 0.4: 1.3, and the reaction temperature in the reactor is 630 ° C.

The waste gas extracted from the top of the tower is formaldehyde 670

ppm, methanol 1700 ppm, methyl formate 720 ppm. A product formaldehyde solution of 3600 kg / hr was obtained, where the product formaldehyde concentration was 54.6% by weight, the methanol concentration was 1.2% by weight, and the formic acid content was 65%.

It was ppm by weight.

[Brief description of drawings]

Patent Citations (5)

Cited By (10)

Abstract

Lead-silver catalysts have been found to be useful in the production of formaldehyde by oxidative dehydrogenation of methanol vapor with an oxygen-containing gas at elevated temperatures.

BACKGROUND OF THE INVENTION

Silver catalysts in the form of granules, gauze, wire turnings, crystals, and the like have been used for many years to produce formaldehyde by the oxidative dehydrogenation of methanol. Silver crystals are especially suitable for this purpose, since they are very selective and have little tendency to promote side reactions and the formation of by-products under reaction conditions which permit high overall yields.

Numerous prior art patents and publications describe the addition of small amounts of promoters to silver catalysts used in the production of formaldehyde from methanol. For example, U.S. Pat. No. 1,937,381, issued to Bond et al on Nov. 28, 1933 and assigned to du Pont, describes silver crystal oxidation catalysts containing promoters such as oxides of tungsten, vanadium, cerium, thorium, molybdenum, chromium, aluminum and zinc. Silver-cadmium alloy catalysts for the oxidative dehydrogenation of methanol are shown in U.S. Pat. No. 3,334,143, issued to Stiles on Aug. 1, 1960 and also assigned to du Pont. Silver containing up to 10% of an oxide of barium, strontium or calcium and up to 8% of an oxide of indium are taught as methanol oxidative dehydrogenation catalysts in U.S. Pat. No. 4,045,369, issued to Cantaluppi on Aug. 30, 1977 and assigned to S.A.E.S. Getters S.p.A. None of these patents suggest the use of lead in combination with silver as a methanol oxidative dehydrogenation catalyst.

Two literature articles from the Soviet Union, each entitled "Catalytic Properties of Silver Alloys in the Conversion of Methanol into Formaldehyde", also disclose various additives alloyed with silver for the oxidation of methanol to formaldehyde. The first is an abstract of The Russian Journal of Physical Chemistry, 45 (10), 1971 p. 1524. It discloses as methanol oxidative dehydrogenation catalysts silver alloys of aluminum, magnesium, copper, zinc, gallium, germanium, selenium, cadmium, indium, tin, antimony, tellurium and bismuth. The other publication is an article from Tekh. Progr. Dostizh Nauki Khim, Prom. 1973, p. 191-5 abstracted in Chemical Abstracts Vol. 81, 68971, 1974. It describes the same silver alloys as the first abstract except that the selenium and antimony alloys are not included. There is no mention of lead-silver catalysts in these articles. Of specific interest, however, is the description of the attempt to improve silver catalysts by adding tin and germanium (or the same group in the Periodic Table as lead) to improve the oxidative dehydrogenation of methanol to formaldehyde. Both of these additives to silver gave exceptionally poor results for formaldehyde production, compared to the use of silver alone.

A paper by Schwab entitled "Metal Electrons and Catalysts" in the The Transactions of the Faraday Society Vol. 42, 1946 p. 689-697, describes heterogeneous and homogeneous alloys of lead-silver, among other alloys. However, these catalysts were used to dehydrogenate formic acid to hydrogen and carbon dioxide, a reaction substantially different from the oxidative dehydrogenation of methanol to formaldehyde.

Another prior art patent, U.S. Pat. No. 3,948,997, issued Apr. 6, 1976 to Howe et al, describes a process for the vapor phase oxidation of α,β-diols such as ethylene glycol to α,β-diones such as glyoxal at elevated temperatures in the presence of a catalyst containing as essential constituents, one or more metals of Group Ib of the Periodic Table comprising copper, silver and gold, and one or more elements from Group IVa, comprising germanium, tin and lead, and Group Va, comprising nitrogen, phosphorus, arsenic, antimony and bismuth. However, there is no specific disclosure in this patent of a lead-silver catalyst, per se, nor is there any suggestion that any of the catalysts disclosed generically or specifically, could be used for the oxidative dehydrogenation of methanol to formaldehyde.

DETAILED DESCRIPTION OF THE INVENTION

The lead-silver catalysts used in the process of the present invention are readily prepared by impregnating lead onto silver. Preferably, the silver base used is silver crystals which are somewhat porous or irregular, e.g., silver crystals having particle sizes ranging from about 8 to about 40 mesh U.S. screen size (i.e. particles which will pass through a 8 mesh screen but which will be retained on a 40 mesh screen). A small amount of silver crystals having a mesh size larger than 8 mesh, i.e., up to about 10 weight percent of the total crystals, can be tolerated in the methanol conversion, but if the amount of large silver particles becomes excessive, the contact of methanol and oxygen with the silver crystals will be significantly decreased, resulting in lessened formaldehyde production. On the other hand, a small amount of silver crystals smaller than 40 mesh (again up to about 10 weight percent of the total catalyst) can be used in the methanol reaction. However, if a significant amount of smaller particles are present, an undesirable increase in the pressure drop across the catalyst bed may be observed. Particularly preferred are silver crystals having particle sizes ranging from about 20 to about 30 mesh (U.S. screen size).

One technique for preparing the catalysts of this invention involves impregnating silver crystals with a decomposable salt of lead, such as lead acetate, lead nitrate, or the like, and then decomposing the lead salt, for example by heat. Lead can also be applied to silver crystals by immersing the crystals in an organic or aqueous solution of a soluble lead salt and evaporating the solvent, preferably while stirring to obtain a more uniform distribution of lead on the silver crystals. Also a suspension or colloidal solution of a lead compound, prepared by any of the ordinary methods, may be flocculated while in contact with silver crystals to give a lead-silver catalyst.

The catalysts used in the process of this invention comprise silver and lead. The amount of lead in the catalyst can range from about 100 to about 150,000 parts per million, based on the total catalyst, and silver can comprise the remainder of the catalyst. The weight ratio of lead to silver on this basis can range from about 0.0001 to about 0.15. The preferred amount of lead in these catalysts can range from about 1000 to about 7000 parts per million, based on the total catalyst, with silver comprising the remainder of the catalyst. The preferred weight ratio of lead to silver can range from about 0.001 to about 0.007.

Lead-silver catalyst can also be prepared by depositing lead and silver on selected catalyst supports, such as silicon carbide or α-alumina, which do not detrimentally affect oxidative dehydrogenation of methanol to formaldehyde under the reaction conditions of the present invention. Such catalysts and processing conditions are described in copending application U.S. Ser. No. 287,385, filed July 27, 1981 in the names of H. R. Gerberich and E. T. Smith assigned to Celanese Corporation and filed concurrently with this application.

The process of this invention can be carried out in any conventional single stage or multiple stage methanol oxidation reactor at elevated temperatures. Individual reactors require facilities to hold a sufficient amount of oxidative dehydrogenation catalyst and to permit the methanol-oxygen mixture to pass over the catalyst to accomplish oxidative dehydrogenation. Downstream facilities to recover the formaldehyde product, normally in aqueous solution, are also required.

In carrying out the process of this invention, a feed mix of methanol and an oxygen-containing stream, such as pure oxygen, a mixture of oxygen and nitrogen, air, or other oxygen sources, i.e., one containing about 5 mol percent to about 100 mol percent of oxygen, is passed into a reactor containing catalyst comprising lead and silver and reacted at a temperature in the range from about 500° C. to about 700° C., preferably about 550° C. to about 650° C. Diluents such as steam and nitrogen, if desired, can be added to the methanol-oxygen mixture in amounts ranging from about 0.1 to about 10 mole of diluent per mole methanol in the feed, and preferably from about 0.75 to about 3 mole of dilute per mole methanol in the feed. The mole ratio of oxygen to methanol in the feed can range from about 0.15 to about 0.8, and preferably from about 0.2 to about 0.5. The space velocity of the feed entering the reactor generally will be maintained at from about 10 to about 150 reciprocal seconds, and preferably at from about 25 to about 80 reciprocal seconds.

Single stage operations, such as described above, although quite widely used to produce formaldehyde, suffer from the disadvantage that rather high amounts of unconverted methanol are contained in the product emerging from the catalyst bed. The presence of methanol in the exiting formaldehyde solution is undesirable since the methanol, generally, must be separated from the formaldehyde using expensive distillation facilities. However, the need for a separation step can be avoided by using a second oxidation stage of reaction. When carrying out a second oxidation, the effluent gases from the first stage reactor can be cooled, preferably below about 250° C., and mixed with an additional oxygen-containing stream, such as air. The use of such a two stage oxidation process is described in U.S. Pat. Nos. 2,462,413; 3,959,383; 3,987,107 and 4,076,754, among others. The effluent gas-oxygen mixture is then passed through a second stage catalytic oxidative dehydrogenation reactor containing sufficient catalyst to convert substantially all of the remaining unreacted methanol to formaldehyde. Temperatures in the range from about 550° C. to about 700° C., and preferably from about 600° C. to about 675° C., generally will be employed, while the space velocity of the gas in the second stage oxidation reactor generally will be maintained in the range of from about 10 to about 200 reciprocal seconds and preferably from about 30 to about 100 reciprocal seconds.

Any catalyst for the conversion of methanol to formaldehyde, and preferably a silver-containing catalyst, can be used in the second oxidation stage. Lead and silver catalysts, such as those used in the first stage oxidation reaction described above, can be used in the second stage as well. Conventionally used silver crystals, with or without other additives, can also be used.

The effluent gas emerging from the second stage can be passed through a cooler and then passed into the base of an absorber column. A stream of water may be introduced at the top of the absorber column in order to adjust the formaldehyde concentration in the aqueous formaldehyde product which is removed from the bottom of the column. The non-condensable gases entering the absorber are vented at the top of the column to an incinerator or to the atmosphere.

The advantages of the invention can be seen by reference to the following examples

EXAMPLE 1

The unpromoted silver used in this and the following examples as a catalyst per se, as well as a base for the promoted catalysts of the present invention, was 20 to 30 U.S. screen mesh size silver crystals, electrolytic grade, 99.9% purity. To produce the promoted catalysts, an appropriate amount of lead acetate, antimony di-tartrate, or bismuth nitrate was impregnated on the silver crystals.

This was accomplished by first adding a solution of the desired metal salt to the silver crystals using an amount of solution just sufficient to cover the crystals. The liquid was then removed under vacuum, as a vapor, by heating. As an illustration, to prepare a silver catalyst containing 10,000 parts per million lead, lead acetate [Pb(OAc)2.3H2 O)] in the amount of 0.46 gram was dissolved in demineralized water to make 5.8 ml of solution. This solution was poured onto 25 grams of silver crystals. The water solvent was then removed under vacuum at 100° C.

In preparing the antimony-containing catalysts, antimony di-tartrate, which is soluble in demineralized water, was poured on silver catalysts and the aqueous solvent removed by vaporization under vacuum at 100° C. In preparing the bismuth-containing catalysts, bismuth nitrate, dissolved in methanol containing a minor amount of concentrated nitric acid added to aid in the solubilization, was poured on silver crystals and the excess methanol removed by vaporization under vacuum at 100° C. After the catalysts were prepared, they were placed in the catalyst bed of the methanol oxidation unit.

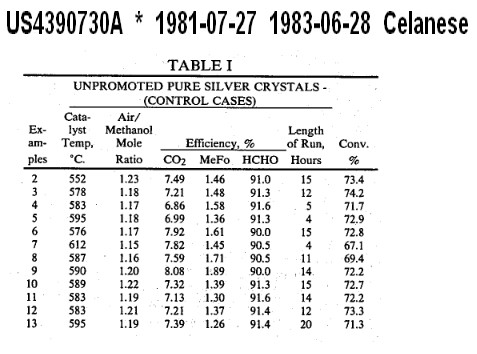

EXAMPLES 2-16

The methanol oxidation unit used for these examples was an insulated, cylindrical reactor made of 316 stainless steel which is 7 inches long and has an internal diameter of 7/8 inch. In each run the reactor contained 17 grams of unpromoted silver catalyst. The catalyst bed was 0.5 inch deep. A thermocouple inserted into the catalyst bed was used to measure the reaction temperature. Air [7605 cc (STP)/min] was sparged into a heated vessel of liquid methanol. The gas leaving this vaporizer contains air to methanol mole ratio of 1.15 to 1.24. This vapor stream was mixed with a flow of pure nitrogen (1949 cc/min) and heated to 125° C. to avoid condensation. The mixture was fed to the methanol oxidation unit described above. Reaction was initiated by heating the catalyst bed with an electrical resistance winding which is on the external surface of the reactor. As soon as the methanol conversion reaction occurred as indicated by a sudden rise in temperature to 450° C. or above the timing of the run was begun. The conversions of methanol, which ranged from about 69 to about 76 percent, were collected by keeping the air and thus the oxygen in the feed stream constant and varying the oxygen-methanol ratio by controlling the methanol in the stream, with higher oxygen-methanol ratios yielding higher methanol conversions. Once the reaction, which is exothermic, was initiated, the temperature was permitted to reach its own level, with no external heat being added to the reaction and no heat being deliberately absorbed by heat exchangers while the reaction is continuing, although an undetermined amount of heat may of course have escaped into the surroundings through the reactor walls. The product stream is analyzed by gas chromatography for mole percent nitrogen, oxygen, methanol, carbon dioxide, carbon monoxide, hydrogen and methyl formate. Data were collected for the period of 5 to 20 hours after initiation of the reaction. The conditions of the reaction were:

catalyst temperature-545°-612° C.

reaction pressure-5.8 psig

oxygen conversion-99.5 percent

space velocity-51 sec-1

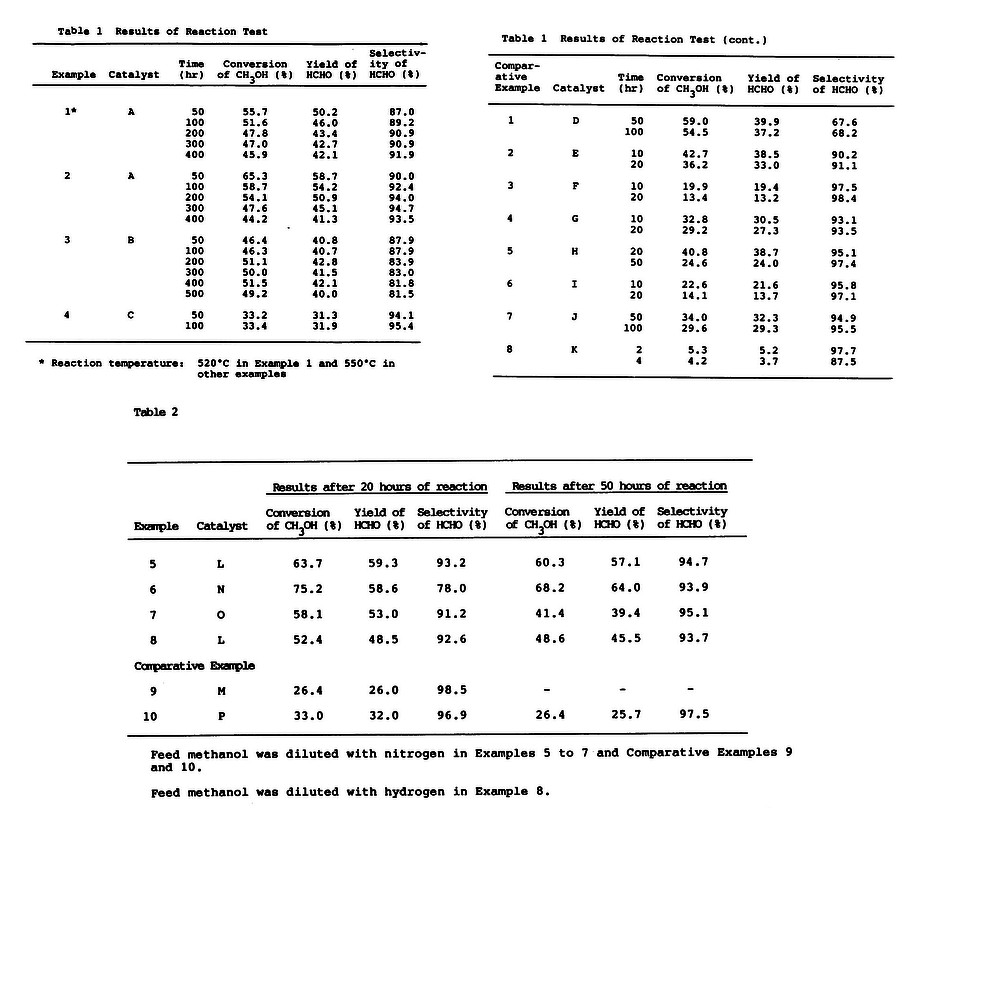

Table I sets out the results of the methanol oxidative dehydrogenation to formaldehyde using the unpromoted silver crystals for comparison with the promoted catalysts under the conditions set forth above. The table indicates catalyst temperatures used in the reaction, length of run, conversions of methanol to total products, and the efficiencies of converted methanol to carbon dioxide (CO2), methyl formate (MeFo) and formaldehyde (HCHO).

*************************************************************************************************

Abstract

The invention discloses a production process of paraformaldehyde, which comprises the following steps: comprises a formaldehyde evaporation process, a methanol oxidation process, a formaldehyde absorption process, a formaldehyde concentration process and a paraformaldehyde drying process. The invention belongs to the technical field of paraformaldehyde production, and particularly relates to a paraformaldehyde production process, which is characterized in that methanol and air are used as raw materials, the production process comprises the working procedures of catalytic oxidation, absorption and the like, the methanol is subjected to catalytic dehydrogenation to obtain formaldehyde, the formaldehyde is absorbed by water to obtain a 37% formaldehyde solution, the formaldehyde solution is concentrated, and a vacuum rake dryer is used for drying and producing the formaldehyde solution to obtain a paraformaldehyde finished product.

Description

Paraformaldehyde production process

Technical Field

The invention belongs to the technical field of paraformaldehyde production, and particularly relates to a paraformaldehyde production process.

Background

Paraformaldehyde is a product produced by dehydration, concentration, drying and polymerization of an aqueous formaldehyde solution, is a mixture of formaldehyde molecules, namely polyoxymethylene glycol HO (CH2O) nH and the like, and is a linear polymer important in chemical engineering.

Disclosure of Invention

In order to solve the problems, the invention provides a paraformaldehyde production process.

In order to realize the functions, the technical scheme adopted by the invention is as follows: a production process of paraformaldehyde comprises the following steps:

1) a methanol evaporation process: air is sent into an air washing tower by an air fan, the air enters a methanol evaporator after being washed by water, methanol is sent into the methanol evaporator from a tank area by a pump, the methanol feeding flow is interlocked with the air feeding flow, the feeding proportion is controlled, the formaldehyde liquid generated by the No. 1 absorption tower is used as a heat source to exchange heat with the methanol liquid in the methanol evaporator, so that the temperature of the methanol liquid is raised, and then the methanol gas is generated by bubbling through the air;

2) a methanol oxidation step: introducing a certain amount of water vapor of 0.4MPa and 152 ℃ supplied by an oxidizer steam drum at the top of a methanol evaporator, mixing the water vapor with methanol gas, feeding part of tail gas generated by subsequent reaction into the methanol evaporator through a tail gas fan in proportion to air so as to utilize the heat energy of the tail gas to heat the methanol gas, heating the mixed gas consisting of the methanol gas, the air, the steam and the tail gas containing a small amount of methanol gas to 110 ℃ through pyrogen steam, and sending the mixed gas to a subsequent oxidation section;

3) wherein, the methanol oxidation process comprises the following reaction steps:

CH3OH+1/2O2→CH2O+H2O△H=+156.557kJ/mol CH3OH→

CH2O+H2△H=-85.27kJ/mol

side reaction:

CH3OH+O2→CO+2H2O CH3OH+3/2O2→CO2+2H2O CH2O+

1/2O2→HCOOH HCOOH→CO+H2O;

the mixed gas enters an oxidizer at 110 ℃, is subjected to oxidation reaction under the catalysis of an electrolytic silver catalyst at 580-650 ℃ to generate formaldehyde gas, emits a large amount of heat, soft water is introduced into a jacket of the oxidizer to remove the reaction heat, the water is converted into steam, the steam enters a steam pocket of the oxidizer, the steam is supplied for production between the oxidizer and the oxidizer through a steam distributor, the rest of the steam is introduced into a steam pipe network of a plant area, and meanwhile, the formaldehyde gas at the outlet of the oxidizer is cooled to about 180 ℃;

4) a formaldehyde absorption procedure: the formaldehyde gas generated in the methanol oxidation process is sequentially sent into a 1# absorption tower and a 2# absorption tower for water spraying absorption, tail gas is led out from the top of the 2# absorption tower and is sent to a tail gas boiler, fresh water is supplemented from the top of the 2# absorption tower and is in countercurrent contact with synthesis gas to absorb formaldehyde, a dilute formaldehyde solution extracted from the bottom of the 2# absorption tower is pumped into the 1# absorption tower and is in countercurrent contact with the synthesis gas entering the 1# absorption tower, and the formaldehyde solution (with the concentration of about 37%) is extracted from the bottom of the 1# absorption tower and is sent to a formaldehyde intermediate tank for temporary storage.

5) A formaldehyde concentration procedure: conveying 37% of formaldehyde solution from a formaldehyde intermediate tank into a first-effect evaporator, heating to 80 ℃ under negative pressure for evaporation concentration, mixing gas and liquid, keeping the temperature of 80 ℃, feeding the mixture into a first-effect separator, feeding water vapor from the upper side of the first-effect separator into a vacuum absorption tower for absorption, conveying 55% of concentrated formaldehyde at the bottom of the first-effect separator into a concentrated formaldehyde kettle, and keeping the temperature of the concentrated formaldehyde at 80 ℃ by using a 95 ℃ hot water jacket for heat tracing through a pipeline between the first-effect separator and a dryer and tank equipment so as to prevent the concentrated formaldehyde from self-polymerization;

6) and a paraformaldehyde drying procedure:

the formaldehyde polymerization equation is as follows: nHCHO → (CH2O) n (n ═ 8 to 100)

55% concentrated formaldehyde circularly conveyed by a concentrated formaldehyde kettle is conveyed to a vacuum rake dryer, 50% liquid caustic soda is quantitatively mixed in a liquid caustic soda metering tank, and the liquid caustic soda is pumped into the vacuum rake dryer by a liquid caustic soda feeding pump to catalyze formaldehyde polymerization, so that the formaldehyde polymerization speed is accelerated: introducing 151 ℃ steam into a jacket of the vacuum rake dryer to control the reaction temperature of the materials to be 80 ℃, simultaneously vacuumizing to ensure the negative pressure of the equipment, feeding concentrated formaldehyde and liquid caustic soda into the vacuum rake dryer for polymerization and drying, feeding the dried product into a paraformaldehyde packaging bin, packaging, and conveying to a polyformaldehyde shed area for storage and sale;

7) the tail gas burning contains combustible substances such as H2, CH2O, CH3OH, CO and HCOOH in unabsorbed gas (namely tail gas) that comes out from the top of the 2# absorption tower, part of tail gas is recycled, the tail gas is sent into the methanol evaporator through the tail gas fan to participate in the reaction, the rest tail gas is sent into the tail gas boiler to burn, the tail gas burning generates a large amount of heat, soft water is introduced into the coil pipe of the tail gas processor, the soft water enters the tail gas steam pocket after heat exchange, the generated steam is merged into the steam pipe network of the plant area, and the waste gas generated after the tail gas burning is emptied through the exhaust funnel.

Further, the alcohol feeding flow rate and the air feeding flow rate are interlocked in the step 1), and the feeding proportion is controlled, so that the feeding oxygen-alcohol ratio is kept between 0.39 and 0.45.

Further, the ratio of the oxygen alcohol steam ternary gas in the step 2) is as follows: oxygen: methanol: steam 0.39: 1: 0.25-0.45: 1: 5.

the invention adopts the structure to obtain the following beneficial effects: the production process of the paraformaldehyde provided by the invention is simple to operate, compact in mechanism and reasonable in design, and comprises the following steps: comprises a formaldehyde evaporation process, a methanol oxidation process, a formaldehyde absorption process, a formaldehyde concentration process and a paraformaldehyde drying process. Methanol and air are used as raw materials, the production process of the procedures of catalytic oxidation, absorption and the like is carried out, the methanol is subjected to catalytic dehydrogenation to obtain formaldehyde, the formaldehyde is absorbed by water to obtain a 37% formaldehyde solution, and the formaldehyde solution is concentrated and dried by a vacuum rake dryer to obtain a paraformaldehyde finished product.

Detailed Description

Patent Citations (6)

Similar Documents

Priority And Related Applications

********************************************************************************

A kind of method for preparing anhydrous gaseous formaldehyde

Abstract

The invention discloses a kind of method for preparing anhydrous gaseous formaldehyde, methods described sequentially includes:(1) carry out formaldehyde and prepare reaction;(2) formaldehyde in alcohol absorption step (1) is used to prepare the product reacted;And (3) by the product heats in previous step to 125 to 180 DEG C to discharge anhydrous gaseous formaldehyde.By the present invention, anhydrous gaseous formaldehyde can be directly obtained, and technique is simple, flow is short, and more other anhydrous gaseous formaldehyde preparation method energy consumptions are greatly reduced, and avoid the participation of extra water, so as to which wastewater discharge is also greatly decreased.

Background technology

Formaldehyde is a kind of important Organic Ingredients in chemical field, and its property is active, mainly as production agriculture The raw material of the materials such as medicine glyphosate, phenolic resin, Lauxite, polyacetal resin, melamine resin and centre Body, it is widely used in coating and field of pesticides.

The method of industrial production formaldehyde is very ripe at present, uses methanol oxidizing process mostly, i.e., in silver, copper etc. In the presence of metallic catalyst Oxidation of Methanol is to generate the method for formaldehyde, here, in the oxidizing gas of generation All using water come spray-absorption formaldehyde in absorption, so as to finally give 37%-40% formalin.

But required in the production process of many products using anhydrous formaldehyde, such as resinae, special agricultural chemicals Class etc., and demand is larger.Obtain anhydrous formaldehyde, it is necessary to which presently commercially available formalin is entered Row distillation operation, this will not only put into more considerable equipment, operating cost, and formaldehyde can also be with water shape Into azeotropic mixture, the difficulty of separation is further increased.Or, it is desirable to it can also be adopted in anhydrous reaction With paraformaldehyde, still, the preparation process of paraformaldehyde is also required to formalin being concentrated by evaporation, dried Deng can equally consume substantial amounts of energy, this is not economic and environment-friendly enough.It also proposed in recent years in catalyst In the presence of make methanol direct dehydrogenation generation formaldehyde and hydrogen method, the method reaction after do not generate water, can Directly obtain anhydrous formaldehyde.However, the problem of methods described is present is catalyst easily poisoning and inactivation, circulation Utilization rate is poor, thus also only resides within laboratory demonstration and improved stage, there is not yet large-scale production Report.

Therefore, according to the current method by producing formaldehyde by methanol oxidation, a kind of new production nothing is developed The technique of water beetle aldehyd

According to another implementation of the invention, the formaldehyde prepares reaction and can also be natural gas oxidizing process Or methanol dehydrogenation method etc..Wherein, the main reaction such as following formula of the natural gas oxidizing process (namely for methane oxidizing process) Shown in 2.

[formula 2]

CH4+O2→H2O+HCHO

Also, in the natural gas oxidizing process, used catalyst is this area catalytically oxidizing natural gas (methane) be made formaldehyde custom catalystses, for example, MoO3/SiO2、V2O5/SiO2、Cr2O3/SiO2、 Fe-Mo-Co、Mo/ZrO2Deng catalyst, but the present invention is not limited to this.It is further, since described natural Product in gas oxidizing process also includes water, so the present invention's prepares the method for anhydrous gaseous formaldehyde in step (2) (3) can also further comprise the absorbent of gained in step (2) being evaporated under reduced pressure between to remove moisture Process.

Wherein, the main reaction of the methanol dehydrogenation method is as shown in following formula 3.

[formula 3]

CH3OH→H2+HCHO

Also, in the methanol dehydrogenation method, used catalyst is this area catalysis methanol direct dehydrogenation So that the custom catalystses of formaldehyde are made, for example, Ag/SiO2-ZnO、Ag/SiO2The catalyst such as-MgO, but The present invention is not limited to this.In addition, although the main reaction of the methanol dehydrogenation method does not produce water, but according to Need, the method for preparing anhydrous gaseous formaldehyde of the invention also can be between step (2) and (3) further Including the absorbent of gained in step (2) is evaporated under reduced pressure with dewatered process.

In the present invention, the product that the formaldehyde prepares reaction be gas phase, and it refers to chemically reacting from passing through Generate the derived gas-phase product mixture for including formaldehyde, the gas-phase product mixture in the reactor of formaldehyde May contain unreacted raw material (such as methanol, oxygen, CO), reaction product (for example, formaldehyde, Water, hydrogen etc.) and other foreign gases and/or side reaction product gas etc., wherein the formaldehyde included can To generate hemiacetal with alcohol in procedure described above (2), so as to be dissolved in alcohol, meanwhile, alcohol is again The good solvent of formaldehyde, thus the alcohol not still condensing agent of formaldehyde, or the solvent of formaldehyde.

Therefore, according to an embodiment of the invention, the alcohol can be selected from saturation unitary, binary, One or more in more polynary aliphatic alcohol and polyethylene glycol, poly- propyl alcohol etc..In addition, it is optional, when When the alcohol is aliphatic alcohol, one or more hydrogen on its alkyl chain part can also be by other substituent institutes Substitution, the substituent can be, for example, methyl, hydroxymethyl, cyclohexyl etc..

Preferably, the alcohol can be one kind or more in cyclohexanol, nonyl alcohol, polyethylene glycol and glycerine Kind.By using alcohol enumerated above, formaldehyde can be quickly dissolved and absorbed.

Preferably, the alcohol can be the polyethylene glycol that weight average molecular weight is 200 to 400.In addition, formaldehyde Maximum level in the polyethylene glycol that the weight average molecular weight is 200 to 400 is 50wt%, herein, The maximum level refers to the concept of the amount for the whole formaldehyde that can enter in the polyethylene glycol phase, i.e., at this With the amount of whole formaldehyde existing for hemiacetal state and free state in polyethylene glycol.

Wherein, in step (2), the mol ratio that the alcohol prepares the formaldehyde in product with step (1) is 0.1-3:1, preferably 0.5-1.5:1, more preferably 1:1.

Wherein, the temperature conditionss when gas-phase product is absorbed by alcohol are 10-100 DEG C, preferably 30-80 DEG C, More preferably 60 DEG C.At this temperature, alcohol can effectively dissolve the formaldehyde in the gas-phase product and be formed therewith Hemiacetal.

In the present invention, the reactor for implementing the step (2) does not limit particularly, as long as it is can Realize the reactor of the abundant exchange of gas-liquid, the example may include, but be not limited to, spray column etc. all Plate column and packed tower etc..

According to an embodiment of the invention, the pressure of the vacuum distillation between the step (2) and (3) Power condition is 100-10mmHg, preferably 40-10mmHg, more preferably 20mmHg, and the decompression The temperature conditionss of distillation are 40 to 80 DEG C, preferably 50-70 DEG C, more preferably 68 DEG C.In this temperature and pressure Under the conditions of, water that can to greatest extent in removing step (2) in the absorbent of gained, it is ensured that the present invention is most The water content of anhydrous formaldehyde made from end minimizes, simultaneously because the decomposition bar for the hemiacetal that the present invention is formed Part is more than 125 DEG C, therefore will not also cause the decomposition of hemiacetal in alcohol, avoids the loss of formaldehyde.

In the present invention, the reactor for implementing the vacuum distillation does not limit particularly, as long as it is can be real The reactor being now evaporated under reduced pressure, the example may include, but be not limited to, thin film evaporation tower etc. all be applicable Plate column and packed tower.It by the vacuum distillation process according to the present invention, can contain the dehydrate of generation Water reaches 0.001-0.01wt%, preferably 0.001wt%.

According to an embodiment of the invention, the temperature conditionss of the process of step (3) are preferably 130-170 DEG C, More preferably 140-160 DEG C;And pressure condition is normal pressure to 0.5MPa, preferably normal pressure to 0.4MPa, More preferably normal pressure is to 0.2MPa.Under the conditions of this temperature and pressure, no water beetle can be obtained with stability and high efficiency Aldehyde.

In the present invention, the reactor of implementation steps (3) does not limit particularly, as long as it is achievable The reactor of temperature control heating, the example may include, but be not limited to, the tower knot such as plate column and packed tower Structure, while reactor can also be used.

In the yield of the formaldehyde of preparation in accordance with the present invention, i.e. step (3) amount of the formaldehyde of release with It is more than 92% that formaldehyde of the present invention, which prepares the ratio between amount of whole formaldehyde in the gas-phase product reacted,.

[beneficial effect]

Embodiment 1

The preparation that formaldehyde is carried out using methanol oxidizing process is reacted, and the gas that content of formaldehyde is 30% afterwards is from methanol Column overhead discharge is aoxidized, temperature is down to after 60 DEG C, enters spray tower bottom with 330kg/h flow, together When polyethylene glycol (weight average molecular weight 300) with 1000kg/h flows from spray column top spray, so as to It is 16wt% to content of formaldehyde, content water is 5.4wt% formaldehyde absorption thing.The absorbent is through pump afterwards Squeeze into thin film evaporation tower, be dehydrated, contained under conditions of 68 DEG C of temperature, vacuum 25mm mercury column Water is 0.005wt% dehydrate.The dehydrate is passed through pyrolysis tower with 1100kg/h speed, 155 DEG C are pyrolyzed with heating under normal pressure, so as to obtain the formaldehyde gas that water content is 0.3wt%, yield 96%.

Calculation formula:The amount for the formaldehyde that formaldehyde yield=pyrolysis obtains/formaldehyde is prepared in the gas-phase product of reaction The amount * 100% of formaldehyde

Patent Citations (3)

Cited By (7)

Similar Documents

*********************************************************************************************

CH3OH --->HCHO + H2

CN CN105170145A 王峰 中国科学院大连化学物理研究所

Priority 2014-06-20 • Filed 2014-06-20 • Published 2015-12-23

The invention provides a catalyst for preparing anhydrous formaldehyde through anoxic dehydrogenation of methanol. The catalyst is a metal oxide supported precious metal nanoparticle. When the catalyst is applied in a reaction for preparing anhydrous formaldehyde through direct dehydrogenation of …

Abstract

The invention provides a catalyst for preparing anhydrous formaldehyde through anoxic dehydrogenation of methanol. The catalyst is a metal oxide supported precious metal nanoparticle. When the catalyst is applied in a reaction for preparing anhydrous formaldehyde through direct dehydrogenation of methanol, the reaction is carried out at a low temperature, anhydrous formaldehyde is obtained in a high selectivity manner, and the catalyst has high catalytic activity and long service life.

Background technology

Formaldehyde is a kind of important organic basic industrial chemicals, and in macromolecular material, fine chemistry industry, organic synthesis, medicine intermediate synthesis, fine perfumery synthesis, dyestuff etc., have special applications, economic benefit is very remarkable.Along with the rise of the engineering plastics of synthesized high-performance, PARA FORMALDEHYDE PRILLS(91,95) demand is increasing, and PARA FORMALDEHYDE PRILLS(91,95) concentration requirement is day by day harsh.The existence of water have impact on the exploitation of formaldehyde downstream product.When Lauxite, the phenolic resins of synthesized high-performance, concentration of formaldehyde directly has influence on rate of polymerization and the degree of polymerization, affects the performance of product.And industrial formaldehyde is mainly produced by methanol air oxidizing process, formaldehyde water content is up to more than 50%.The production of anhydrous formaldehyde generally adopts rare aldehyde concentration technology and solvent azeotropic dehydration concentration technology, and because the vapour pressure of formalin is very low, easily form azeotropic system, dehydration separating effect is not good, and energy consumption is large, and isolation andpurification anhydrous formaldehyde is very difficult and expensive.On the other hand, in methanol air oxidizing process, the oxidizable formic acid of formaldehyde, etching apparatus.Therefore, in the urgent need to studying new process, directly produce anhydrous formaldehyde to meet the needs in market by methyl alcohol.

Methyl alcohol direct dehydrogenation is a kind of effective ways preparing anhydrous formaldehyde.The series of problems such as the stability of formalin and purification are all easy to solve.At present, more catalyst mainly a series of metal oxide, slaine, molecular sieve and metal is studied.The research of metal oxide catalyst mainly concentrates on CuO/SiO 2and ZnO/SiO 2.Result of study shows, these catalyst all have good activity and selectivity, wherein ZnO/SiO 2catalyst activity is higher, but stability is generally poor.Weisgickl etc. are with Na 0.5li 0.5alO 2for catalyst, can obtain 98% methanol conversion and 75% formaldehyde selective, but its reaction temperature will up to 900 DEG C, and require harsher to reactor, energy consumption is high, uneconomical.Matsumura etc. are with the ZSM-5 molecular sieve of dealuminzation for catalyst, and formaldehyde yield is 22%.Fudan University Dai Weilin and Fan Kangnian etc. have studied loaded Ag catalyst, has good effect in methanol dehydrogenation.Research finds Ag +be activated centre, in course of reaction, be easily reduced into metallic state and inactivation.At present, report methyl alcohol anaerobic dehydrogenation reaction generally carry out under the high temperature conditions, under hot conditions, formaldehyde is selective low, there is the problems such as carbon distribution.Meanwhile, under high temperature and reducing atmosphere, catalyst is easily reduced fast deactivation.Therefore, be badly in need of exploitation and prepare novel low temperature catalyst, suppressing side reaction generation and catalysqt deactivation.

Summary of the invention

The object of this invention is to provide the catalyst that a kind of methyl alcohol anaerobic dehydrogenation prepares anhydrous formaldehyde, under catalyst action, under anaerobic, cryogenic conditions, methyl alcohol direct dehydrogenation, high selectivity obtains anhydrous formaldehyde.

Conventional methanol anaerobic dehydrogenation process, adopts higher reaction temperature, and high temperature easily makes side reaction occur, and reduces the selective of formaldehyde.The present invention adopts the noble metal nano particles catalyst of support type, realizes the methanol dehydrogenation under cryogenic conditions, reduces the generation of side reaction.The active component of catalyst is one or more in Au, Pd, Pt, Ru metal, and the carrier of catalyst is MgO, CeO 2, ZrO 2, TiO 2, Al 2o 3, one or more in CaO.The load capacity of noble metal is 0.2-15wt%, preferred 0.5%-5.0%.Noble metal nano particles particle diameter is 1-5nm.

The preparation process of catalyst with metal nanoparticles loaded is as follows: the metal component soluble-salt aqueous solution of the 1wt% of certain mass and the protective agent PVPK10 of certain mass are dissolved in 40mL deionized water; then, 0.4wt% sodium borohydride or the reduction under PVPK10 protection of the potassium borohydride aqueous solution of certain volume is added under agitation.This solution, in 20mL ethanol, joins in above-mentioned solution by 0.2g support dispersion, stirs 12h, solvent evaporate to dryness, washing 3-5 time, 80 DEG C of dry 12h.Obtained catalyst screening 20-40 order.

Reaction adopts fixed bed quartz tube reactor on-line measuring device, inserts in quartz reactor, use argon gas purge by obtained catalyst, and the air that removing inside retains and impurity, carry out preheating under argon shield; Wherein methyl alcohol volume content is 10%-60%; Reaction temperature is 100-400 DEG C; The mass space velocity of bed is 5-85mLg -1 cats -1; Particular methanol volume content is 35%-55%; Reaction temperature is 200-300 DEG C; The mass space velocity of bed is 20-55mLg -1 cats -1.

Catalyst tool provided by the invention has the following advantages: the catalytic activity of catalyst is high, (is less than 400 DEG C) at relatively low temperature and reaches high conversion ratio and selective.

Detailed description of the invention

Embodiment 1

Weigh 0.83g1wt%HAuCl 43H 2the O aqueous solution and 0.1gPVPK10 are dissolved in 40mL deionized water, then, add 5mL0.4wt%NaBH under agitation 4.20mL is dispersed with 0.2g carrier TiO subsequently 2ethanolic solution join in above-mentioned solution, stir 12h under room temperature condition, solvent evaporate to dryness, wash 3-5 time, 80 DEG C of dry 12h.Catalyst called after: 2wt%-Au/TiO 2(by Au, load capacity is 2wt%), the average-size of Au ion is 2.5nm, and catalyst is numbered 1, and have Electronic Speculum figure to find out, Au nano particle is dispersed on carrier, and particle diameter is about 2nm.

E

Patent Citations (4)

Cited By (7)

Similar Documents

Priority And Related

*****************************************Abstract

The invention relates to a method for preparing anhydrous formaldehyde by methanol dehydrogenation. The method adopts a palladium-indium catalyst (PdIn/SiO) supported by silicon dioxide2) The specific process is as follows: PdIn/SiO2Filling the formed catalyst into a reaction tube, then filling the reaction tube into a fixed bed reactor, injecting methanol by an advection pump under normal pressure, taking inert gas as carrier gas, wherein the methanol feeding ratio is 10-60 vol%, and the methanol feeding speed is 0.10-0.30 mL/(g)cat.Min), reacting at 350-600 ℃, and obtaining the conversion rate of the methanol of 60-80% and the selectivity of the formaldehyde of 65-85% by chromatography. The invention relates to a method for preparing anhydrous formaldehyde by methanol dehydrogenation, which adopts PdIn/SiO2As the catalyst, the catalyst has higher catalytic activity and product selectivity, less by-products, simple preparation process and high thermal stability.

Background

Formaldehyde is an important organic chemical raw material, can be used for producing thermosetting resins such as phenolic resin and melamine resin, and bulk chemicals such as polyformaldehyde, phenolic aldehyde, urotropine and 1, 4-butanediol, and is also a raw material for synthesizing products such as dye, pesticide, disinfectant and adhesive.

At present, the methanol oxidation method is generally adopted industrially to prepare formaldehyde, theoretically, a formaldehyde aqueous solution with the molar ratio of 1:1 is obtained, the vapor pressure of the formaldehyde aqueous solution is low, the formaldehyde and water form an azeotrope, the separation and purification of the formaldehyde are very difficult, and the energy consumption is huge. In recent years, the demand of engineering plastics, urotropine and other medicines with excellent synthesis performance on anhydrous formaldehyde is increasing, and the anhydrous formaldehyde is obtained by removing moisture from industrial formaldehyde aqueous solution at present, so that the direct preparation of the anhydrous formaldehyde is a hot point of research.

The process for preparing formaldehyde by anaerobic dehydrogenation of methanol obtains formaldehyde and byproduct hydrogen, the formaldehyde and the byproduct hydrogen are easy to separate, and the hydrogen is industrial gas with high added value; the process has no water generation, avoids the separation operation of the formaldehyde aqueous solution, and greatly saves the purchase cost and the operation cost of the rectification equipment; the process also avoids the problem that the formic acid generated by the methanol oxidation method corrodes equipment. Therefore, the direct dehydrogenation of methanol to prepare formaldehyde is a process with great industrial prospect.

In recent years, a new anhydrous formaldehyde preparation process with remarkable economic benefit draws high attention at home and abroad, and a great deal of research work is brought forward. Research efforts are currently focused on the development of highly efficient catalysts, including metals and their oxides, alkali metal salts, and molecular sieves, among others. CN102274722A discloses a new type V2O3And a load type V2O3The preparation method shows better activity in the dehydrogenation reaction of methanol. Takagi et al (Takagi K, Morikawa Y, Ikawa T.Chemestryletters, 1985, 14: 527-0Has high selectivity to formaldehyde. CN101961650A discloses a homogeneous coprecipitation method for preparing zirconium-based catalyst and catalyzing methanol to perform anaerobic dehydrogenation, wherein the yield of formaldehyde reaches 60%. Davirin et al (CN1390639A, CN1537673A, CN1544147A) disclose a series of preparation methods of silver-based catalysts for direct dehydrogenation of methanol. The patent CN101147872A takes industrial sodium bicarbonate as a raw material to prepare the anhydrous formaldehyde by catalyzing and preparing the industrial sodium carbonate, and lays a foundation for the industrialization of preparing the formaldehyde by methanol dehydrogenation. Music et al (Music A, Batista J, Levec J. appliedCatalysis A: general, 1997, 165: 115-131) takes a ZSM-5 molecular sieve catalyst as a matrix, and prepares Na-ZSM-5 and Cu-ZSM-5 type molecular sieves by an ion exchange method, thereby obtaining better selectivity in the methanol dehydrogenation reaction. CN105601487A discloses a rare earth complex Ln [ CH ]2(CH2)nR]3·xH2O.yL, the catalyst has higher selectivity to formaldehyde.

Based on the above, the disadvantages of the catalysts currently used for the preparation of anhydrous formaldehyde are: copper particles in the copper-based catalyst are distributed unevenly, are larger, have smaller active surface area and lower activity; the modified molecular sieve catalyst is difficult to regulate and control in acid-base property and has more byproducts; the catalytic activity of conventional carbonates or bicarbonates is relatively inert and the reaction temperature is generally above 700 ℃. The complex catalyst is a homogeneous catalysis process, and the separation energy consumption is large. Therefore, a heterogeneous catalytic system with good stability, high activity and formaldehyde selectivity and mild reaction conditions is developed, and the preparation of anhydrous formaldehyde by methanol dehydrogenation is imperative.

Disclosure of Invention

The invention aims to overcome the defects of the catalyst used for preparing anhydrous formaldehyde at present, such as: the acidity and the alkalinity of the catalyst are difficult to control, and a plurality of byproducts are generated. The patent combines a palladium-indium alloy with higher activity and a nano-silica carrier without a significant acid center to prepare a silica-supported palladium-indium catalyst. The catalyst has the advantages of simple preparation method, high stability, mild reaction conditions and high conversion rate and selectivity.

The invention relates to a preparation scheme of anhydrous formaldehyde, wherein the preparation of the anhydrous formaldehyde adopts PdIn/SiO2As a catalyst, the catalyst was molded and charged into a reaction tube, and then charged into a fixed bed reactor. Under normal pressure, methanol is injected by an advection pump, inert gas is used as carrier gas, the methanol feeding ratio is 10-60 vol%, and the methanol feeding speed is 0.10-0.30 mL/(g)catMin), reacting at 350-600 ℃, and detecting a product on line by gas chromatography.

The PdIn/SiO2A catalyst, wherein the content of palladium is 0.5-5 wt% (by mass), and the content of indium is 0.5-5 wt%. The PdIn/SiO2The catalyst is prepared by a coprecipitation method and an impregnation method.

The PdIn/SiO2In the preparation of the catalyst, the soluble precursor salt of palladium is one or two of palladium nitrate, palladium ammonium nitrate and sodium chloropalladate, and the soluble precursor salt of indium is one or two of indium nitrate and indium chloride. The PdIn/SiO2In the preparation of the catalyst, the soluble precursor salt of palladium is preferably one or two of palladium ammonium nitrate and sodium chloropalladate, and the soluble precursor salt of indium is preferably indium chloride. The filling PdIn/SiO2The thickness of the catalyst bed layer is 5-40 mm, the methanol feeding ratio is 10-60 vol% (volume), and the methanol feeding speed is 0.10-0.30 ml/(g)catMin), the reaction temperature is 350-500 ℃. The inert gas is one or more of nitrogen, argon and helium.

This patent discloses silica supported palladium indium catalysts with higher catalytic activity. The active component palladium can activate C-H bonds of methanol and O-H bonds of the methanol, and the introduction of indium effectively adjusts the electronic structure and spatial distribution of the palladium, inhibits the excessive dehydrogenation of the target product formaldehyde at palladium sites, and obviously improves the selectivity of the formaldehyde. And the palladium-indium has no obvious acid site, so that the side reaction of dimethyl ether and water generated by methanol dehydration catalyzed by acid is avoided while methanol dehydrogenation is catalyzed, and the high-purity anhydrous formaldehyde is favorably obtained. In addition, the catalyst related to the patent adopts nano silicon oxide as a carrier, has large surface area, is beneficial to high dispersion of palladium and indium, is not easy to agglomerate and deactivate, and has no obvious acid center, thereby avoiding side reaction caused by the acid center and further improving the selectivity and stability of preparing anhydrous formaldehyde by methanol dehydrogenation.

The specific implementation mode is as follows:

in order to further explain the present invention in detail, several specific embodiments are given below, but the present invention is not limited to these embodiments.

Example 1

Coprecipitation method for preparing (0.5 wt% Pd-0.5 wt% In)/SiO2Catalyst, operating as follows: weighing 2g of nano SiO2(50nm), dispersing in 20mL of water, adding one eachQuantitative Na2PdCl4And InCl3·4H2O, stirring for 1h, and adjusting the pH value of the suspension to 11 by using 30% ammonia water. Stirring for 1H, centrifuging, washing to neutrality, oven drying at 80 deg.C, and drying at 500 deg.C H2Reducing for 2h to obtain (0.5 wt% Pd-0.5 wt% In)/SiO2A catalyst. 2g of the catalyst was weighed, tabletted, molded and packed into a fixed bed reactor. Under normal pressure, nitrogen gas is used as carrier gas, methanol is injected by an advection pump, the volume ratio of the methanol is 10 vol%, the feeding speed of the methanol is 0.30mL/(gcat. min), the reaction is carried out at 350 ℃, the conversion rate of the methanol is 73% by gas chromatography online detection, and the selectivity of the formaldehyde is 66%.

Patent Citations (4)

Similar Documents

*******************************************************************

Patent Citations (42)

Abstract

-

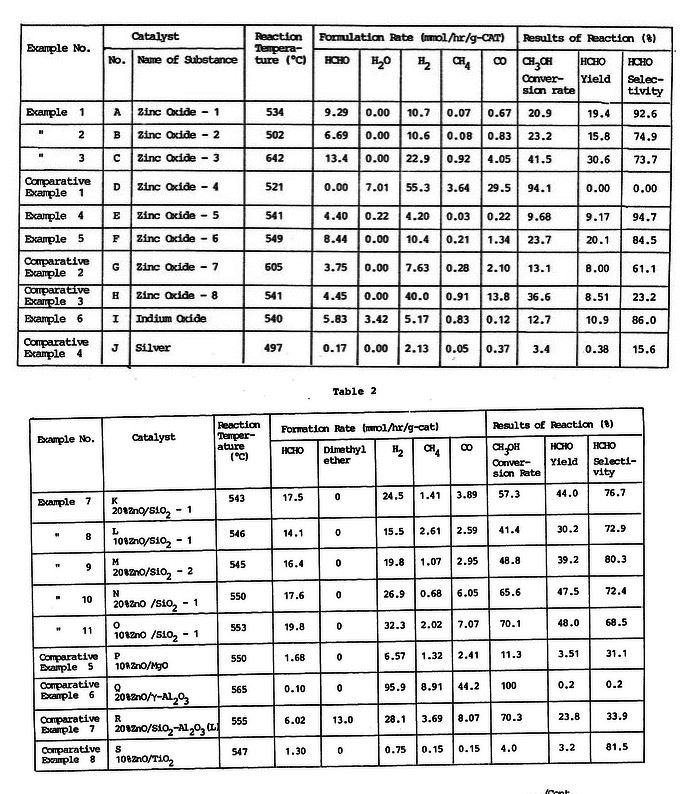

[0048] In a quartz tubular reaction, a mixture of 2.0 g of a sample catalyst and 2.0 g of 40 - 60 mesh fused alumina, which was previously proved to be inert in the test reaction, was charged. Methanol was vaporized and mixed with nitrogen at 150°C, and the gaseous mixture (molor ratio, CH30H/N2 = 36/65) was passed through at atmospheric presusre at 250 m mol/hr, whereby the dehydrogenation of methanol was effected at 500° to 600°C. However, in Examples 3 and 4, a gaseous mixture (molar ratio, CH30H/N2 = 42/58) was fed at 375.9 m mol/hr at atmospheric pressure. In Example 13, a gaseous mixture (molar ratio, CH3OH/N2 = 21/79) was fed at 439.5 m mol/hr at atmospheric pressure and, in Example 14, the molar ratio of methanol to nitrogen was 17/83 and feeding rate of the gaseous mixture was 553.1 m mol/hr at atmospheric pressure. In Examples 13 and 14, no alumina was used and only the sample catalyst was packed in the reactor. -

[0049] The gas exhausted from the reactor was directly introduced, with a sampler, to a gas chromatography (heat electroconductivity type) in which a 3 m column packed with APS-201 20 % Flusin (manufactured by Gasukuro Kogyo Inc.) and a 2 m column packed with molecular sieve 13X are used, and the concentrations of formaldehyde (HCHO), methyl formate, dimethyl ether (DME),hydrogen (H2), carbon monoxide (CO), methane (CH4), unreacted methanol (CH30H at the exit) and nitrogen were measured. The results are given in Tables 1 and 2. The data of Examples 1 to 14 and Comparative Examples 1 to 8 were those measured at 8 to 12 hours after the reaction temperature reached to the previously determined value and therefore of the steady state. Since almost no dimethyl ether and methyl formate were detected with the gas chromatographic analysis, the corresponding data are omitted from the Table 1, but no data are given in Table 2, with respect to

Patent Citations (8)

Cited By (8)

********************************************************************************************************

also

US4054609A

AbstractPURPOSE:Formaldehyde, having good thermal and aging stabilities, is prepared in high yield by the dehydrogenation of methy alcohol in the presence of the catalyst consisting of Cu, Zn and Se.

Description

The present invention relates to a process for the preparation of formaldehyde by dehydrogenation of methanol. More particularly, it relates to a process for the preparation of formaldehyde by the dehydrogenation of methanol in the presence of copper, zinc and selenium as catalyst components.

Catalytic oxidative dehydrogenation, catalytic oxidation and the like are generally known as a commercially available process for the preparation of formaldehyde. According to these prior art processes, formaldehyde is generally obtained as an aqueous solution whose concentration is found to be at most 40% by weight.