rev 16/1/25

Salicylaldehyde

Salicylaldehyde (SA) (C6H4CHO-2-OH) is a useful

aromatic organic chemical. It is a common reactant for many synthesis,

such as cyclic organic compounds like coumarin and organic ligand such

as salen ligand (2 moles of SA + 1 mole of ethylene diamine) The easy synthesis and modifications of the salen ligand framework

made it the platform of choice for the discovery of new catalysts and

reactions.

Salicylaldehyde is

widely used in the production of agricultural chemicals, medicine,

integrated agent; The salicylic aldehyde in low concentration has the

ability of very strong antibacterial activity (example here) ;

As an oxidation inhibitor it can be used in Plastic Resin industry;. It is widely used

in for the synthesis of tonka bean camphor in fragrance industry in

soap, washing composition, compound perfume, candy and tobacco

industry;

It

also serves as a chelating agent with heavy metal ions such as

Copper(II) ion, which is applicable to colorimetric analysis of the

concentration of heavy metal ions in water sample.

As a chemical

intermediate Salicylaldehyde is very often used (some examples here)

Salicylic

aldehyde can form sequestrant with various metals ,propertie used by

the electroplating industry where salicylic aldehyde is used as a

kind of brightener

and levelling agent; In the oil industry, many affixtures of salicylic

aldehyde can improve the high-temperature stability of oil fuel,

gasoline or petrol.; Salicylic aldehyde and derivative thereof are

the raw materials of coumarin, indoline, benzo pyran organic

photosensitive

material, and can synthesize durable hair-setting agent.

Natural

salicylic aldehyde is mainly present in isolated volatile oil, can not

meet human wants far away from embroidery suede chrysanthemum shaddock

plant.

This is a very short list of salicylaldehyde usage ,if you ask for the keyword salicylaldehyde

in title or abstract of GOOGLE PATENT you will get hundreds of

applications for salicylaldehyde in the real world .

PHYSICAL PROPERTIES

SALICYLALDEHYDE

Molecular Formula C7 H6 O2 Synonyms - SALICYLALDEHYDE

- 2-Hydroxybenzaldehyde

- 90-02-8

- o-Hydroxybenzaldehyde

- o-Formylphenol

Molecular Weight 122.12 g/mol pKa 6.8 Specific gravity 1.17 gr/cm3 Ebullition 197°c /760 torr Melting point -7°c Azeotrope with water : Eb=98.4°c ( 20% of salicyladehyde 80% water) Refractive Index : 1.5740 at 20 °C/D Solubility slightly soluble in water; soluble in organic solvents, oils

Taste Nut-like, coumarin flavor at low levels

Used in perfumes, flavoring agents, Reported uses : 1 to 10 ppm)

Occurs naturally in cassia oil; [Ullmann] |  |

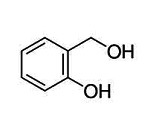

Salicyl alcohol

Synonyms - salicyl alcohol

- 2-HYDROXYBENZYL ALCOHOL

- 90-01-7

- 2-(Hydroxymethyl)phenol

- Saligenin

Molecular Weight 124.14 g/mol

Specific gravity 1.16 gr/cm3

Melting point 86°c

Boiling point 267°c /760 Torr |  |

2 SALICYLALDEHYDE PRODUCTION

Salicyladehyde can be made from commercially available products following different routes :

*2-1 PHENOL/FORMOL processes

*2-2 PHENOL/CHCl3 process (Reimer Tiemann)

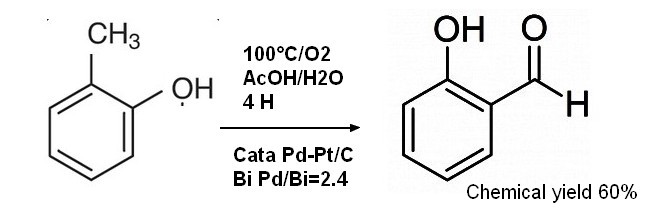

*2-3 ORTHOCRESOL process

* 2-4 Miscellaneous processes

2-1 FORMOL PROCESSES

The reaction consist of making condensation of formol ,generally in the form of paraformaldehyde ( the polymerized

form of formol with a typical degree of polymerization of 8–100

units ) which is a solid melting point 120°c on phenol often without any

solvent

At least 3 process types with variants :

Borate process ,

Cation process ,

Mg process

Formanek process

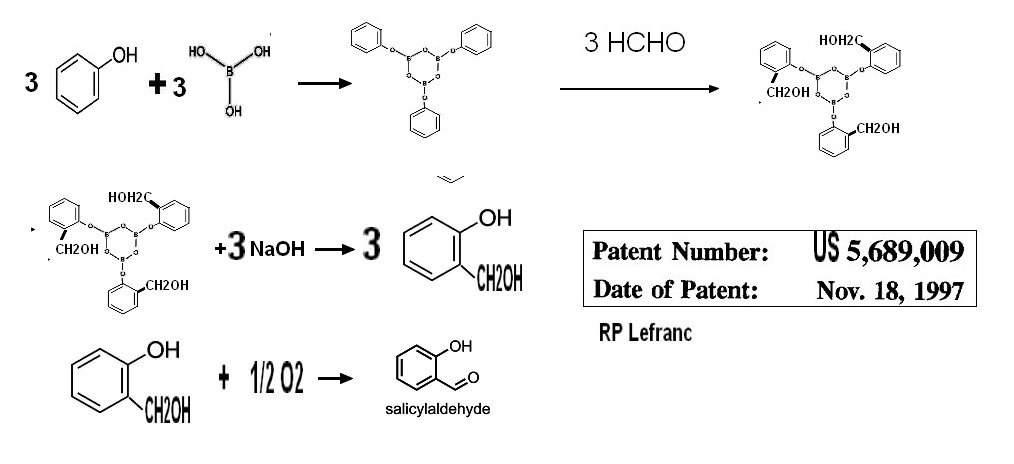

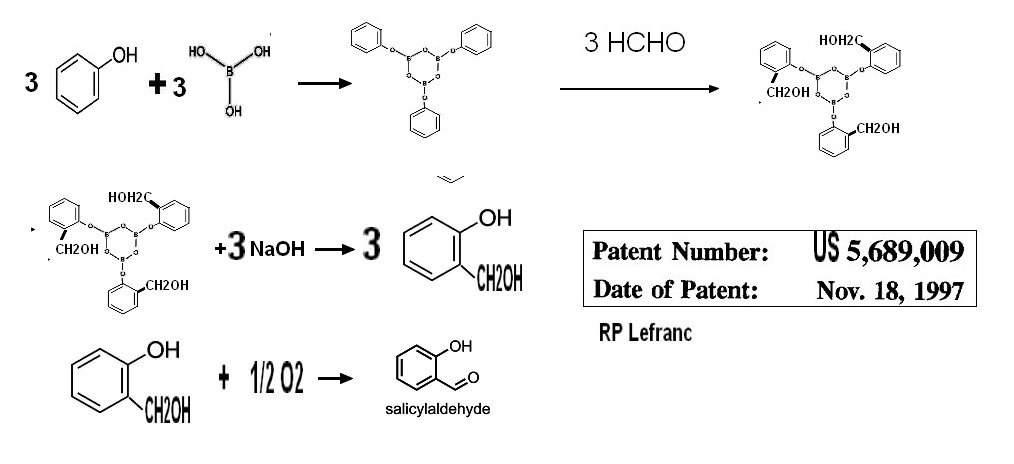

2-1-1"Borate" process

EP 0,327,473 (1/2/1988)

Borate/Formol process (EP0667331A1 Rhodia Chimie SAS Worldwide applications 1994

US5,689,009 nov 18, 1997

Phenol

reacts on boric acid to get "borated phenol" which reacts on formol ,

condesation being made on the ortho position with small amount of para

isomer .The borated saligenol is decomposed with sodium hydroxyde to

get the saligenol .Chemical yield in saligenol is over 87% base on

phenol charged the remainder being unreacted phenol and para

isomer (more details here)

.The aqueous solution of saligenol is directly oxydised with pure

oxygen with a suitable catalyst (either Pt/C + additives or others ) to

get salicyladehyde which is isolated by azeotropic distillation

.The overall yield based on phenol charged is around 70%

.The mains drawbacks of this process is to use boric acid

which is not recovered and to give a large amount of phenolic waste

which has to be treated to comply to local regulations .

Details on lab procedure

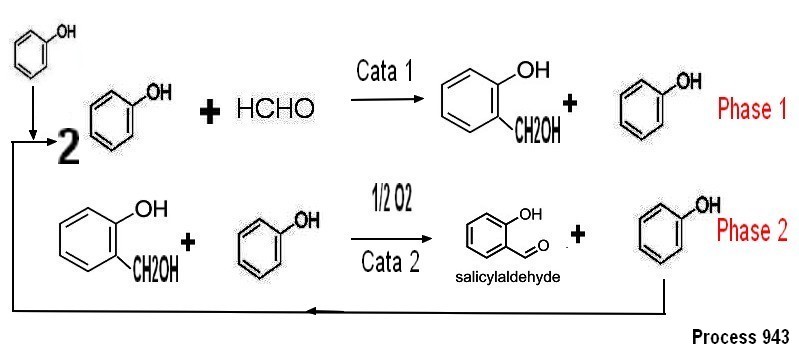

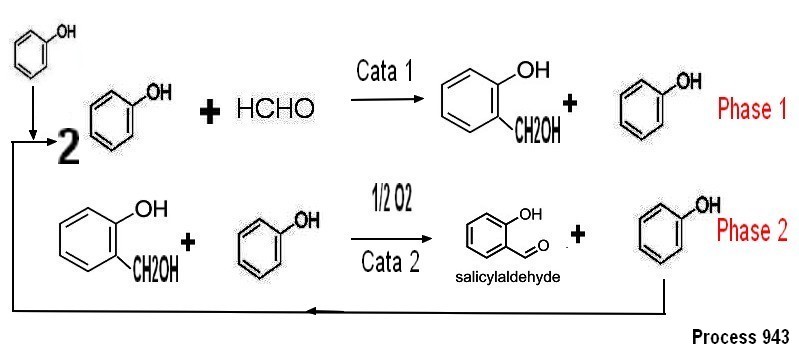

2-1-2"Cation catalyst " process

The

reaction is done by reaction of phenol in excess on formol (for

example 2 moles of phenol/1 mole formol) solvent being Phenol

in

presence of a catalytic amount of a various metal salt (Mono

/di/trivalent like Al,Mg, Cu,Zn,Na...) (typical amount less than 1% on

molar basis compare to formol in the case of homogeneous catalysis ) at

temperature in the 75/85°c

range .By keeping the conversion of phenol under 50% the reaction is

very selective the main by products being the 2,6 diformyl phenol

i and no parahydroxy benzaldehyde It is worth noting that if the

reaction is made not

in anhydrous state but using a formol aqueous solution (37%

formol) the reaction gives a mixture of ortho and para hydroxy

benzaldehyde .Insteadt of using paraformaldehyde ( solid melting

point °c) it is possible to use methanol which is

dehydrogenated into formol vapors on a proprietary catalyst

(microchem proc 943)

Details on lab procedure to make saligenol

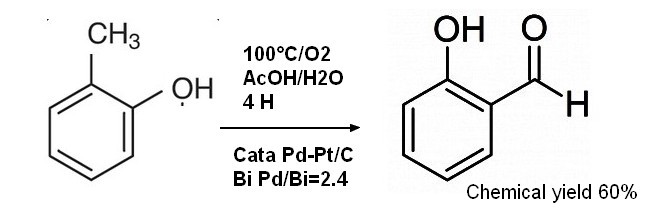

The

oxydation of saligenol to salicylaldehyde can be done directly on the

reaction mixture with oxygen (catalyst Pt/C doped with various

additive like Bismuth to prevent overoxydation to salicylic

acid or

others catalytical systems without any noble metal catalyst such as

copper, nickel, cobalt, iron and manganese.) .It should be noted that

the catalytical system used in phase 1 can be the same as the one of

phase 2 .After oxydation the reaction mixture is distillated

to recover salicylaldehyde (azeotropic distillation) , the phenol

in excess

being extracted and recoverd by vaccum distillation

so as to be recycled . The process

generate a mixture of by products mostly 2,4 and 2,6

diformyl phenol .The

chemical yield for salicylaldehyde on phenol consumed is more than

70% It is a one

pot synthesis in the case of using supported catalyst for

condensation/oxydation .On top of this the process does not

generate any phenolic aqueous waste .

example of lab procedure oxidation with Co chelate here

References of some relevant patents:

*US4026950A

(1975) Inventor Joel Le LudecCurrent

Assignee Rhone Poulenc Industries SA (oxydation

cat Pt/Pd + Bi).

*DE2915216A1 (1979) (Harmann Reimer phenol/formol soude OHB+ PHB

*Process 943 Microchem.fr

*US4460799A (1981) Current Assignee Saint Gobain Isover (cata cond.Al)

*CN1045095A 1989 Process for preparing salicylal from salicylcohol by catalytic oxidation of non-noble metal complex

*EP0069016B1 1985-09-18

Rhone Poulenc (catalyst .Al salt)

*CN

89105025 1989-02-24 catalytic oxidation of salicyl alcohol with non-noble metal complex

Current Assignee Dalian Institute of Chemical Physics of CAS

*US8431750B2; 2008-06-03 Application filed by Rhodia Operations SAS oxidation catalyst

Formol production info

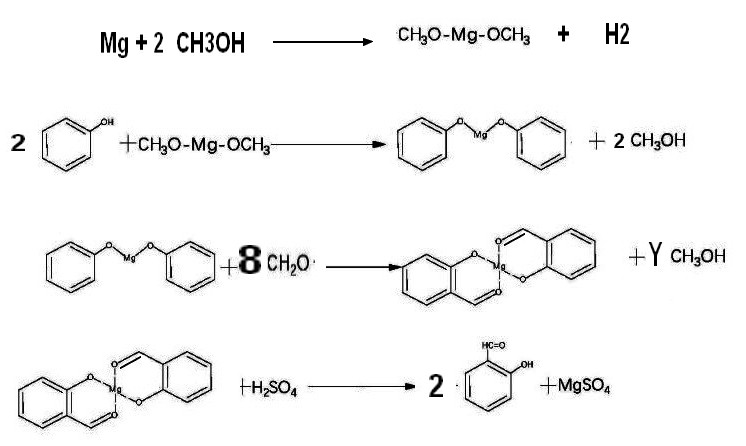

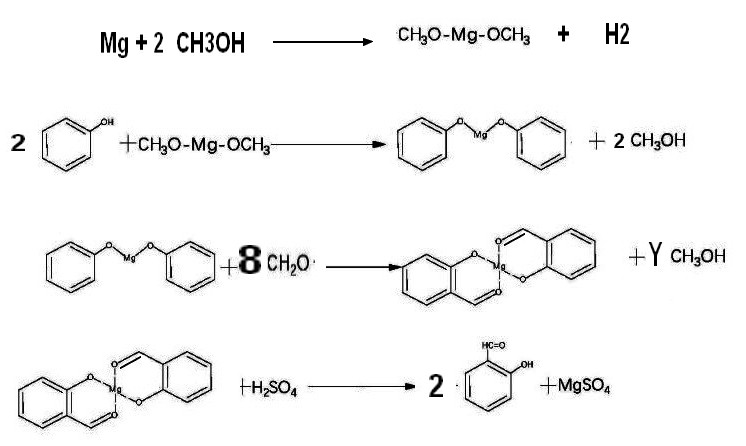

2-1-3"Magnesium" process

CN117164444A

* 2023-09-01 Synthesis method of

salicylaldehyde Current Assignee Zhejiang

Hongda Chemicals Co ltd

CN105669414A 2015-12-09 ,CN117164444A 2023-09-01

The

process use magnesium to get phenol/Mg salt (by reaction of

magnesium methylte on phenol solvent methanol) .The magnesium phenate

reacts with a large

exess of paraformaldehyde (4 times theoritical amount ) to give after

acidification salicylaldehyde .The chemical yiled base on phenol

is in the 80% range .The main drawbacks is the consumption of

Magnesium in stoechiometric amount and the huge amount of

paraformaldehyde

specific consumption for 1 kg of salicyladehyde :Mg=0.17 Kg, Phenol=0.96 kg, Formol=1.07 kg ,H2SO4 100% =0.8 kg

Details on lab procedure

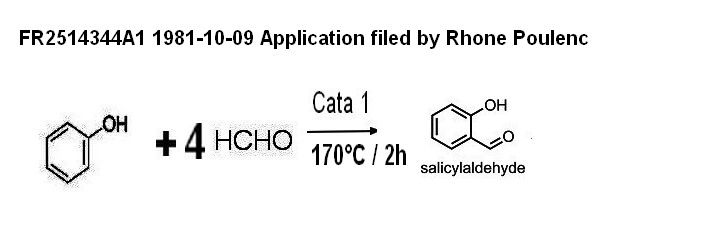

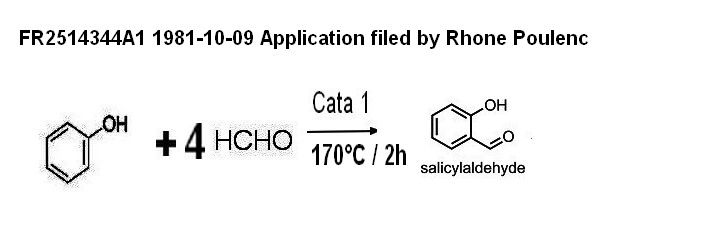

2-1-4 Formanek process

FR2514344A1 1981-10-09 Application filed by Rhone Poulenc

condesation

of phenol on an excess of formol with a catalyst giving

directly salicyl aldehyde (chemical yield 74% on phenol consummed )

proof of concept experiment

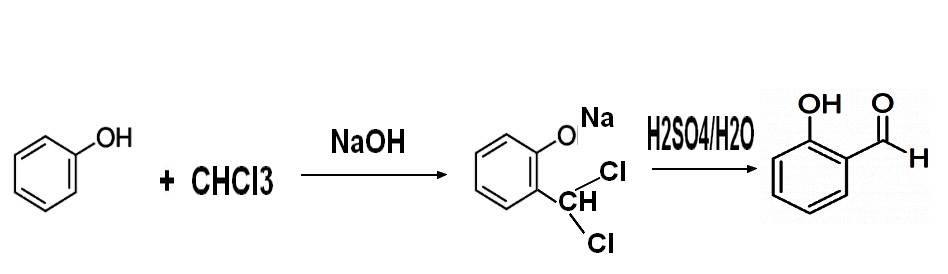

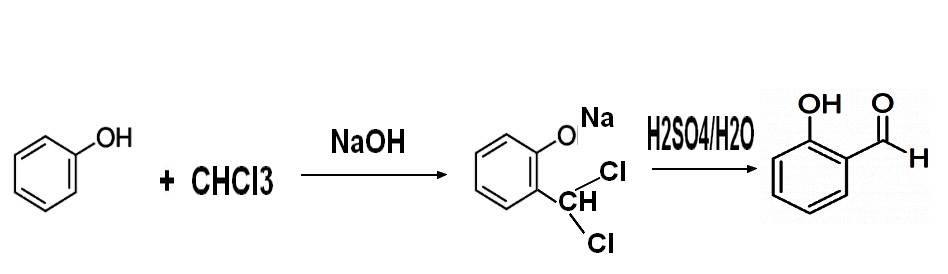

2-2 "Reimer Tiemann" process

Traditional

Reimer-Tiemann method ( Reimer K. Tiemann F Ber.,1876,9,824,1285 and Chem.Review.1960, (60): 1969-1984), take phenol

as raw material in alkaline medium. Phenol is ionized into sodium phenate, and chloroform generates diclorocarben

in this basic media .By reaction on phenate , dichlorocarben first forms

benzyl chloride which is hydrolyzed into aldehyde

through acidification, .The salicylic aldehyde generated is

recovered through azeotropic distillation with water .

This

method is

simple to operate, and raw material are easy to get, but reaction

yield

is in the 50% range based on phenol and even lower on chloroform,

and quantity of alkali consumption is large as the amount of

phenolic wastewater to dipose off. Chloroform is not an expansive product .It is

obtained by chlorination of methane which gives a mixture methyl chloride methylene chloride cholroformes and carbon

tetrachloride ,all these products having an active market .as chemical intermediates or solvents .

This

synthesis is covered by several patents showing how to improve

the yield and selectivity on salicylaldehyde (refer to reference

list)

Although

Reimer-Tiemann method improvement plans emerge

in an endless stream over the years , as for example using used methyl

alcohol (US3365500) or glycol or other solvvant as reaction

medium the chemical yield remains modest in the 60% range .

Some patents references :

US3365500A Hydroxybenzaldehyde process 1964 Current Assignee Dow Chemical Co

US4324922A

* 1979-06-28 1982-04-13 The Dow Chemical

Company Reimer-Tiemann aldehyde synthesis process

US4469894A

* 1981-06-16 1984-09-04 Sumitomo Chemical Co.,

Ltd. Process for preparation of hydroxybenzaldehydes

US4755613A * 1985-07-10 1988-07-05 Institut National Polytechnique

Details on lab procedure for Riemer process (example from beta naphtol) ,lab procedure DOW ,

Chloroform

which can be produced by reaction of chlorine on methane has a large market

.It is a main intermediate for various chemicals as R-22

and PTFE , more details here on its production .

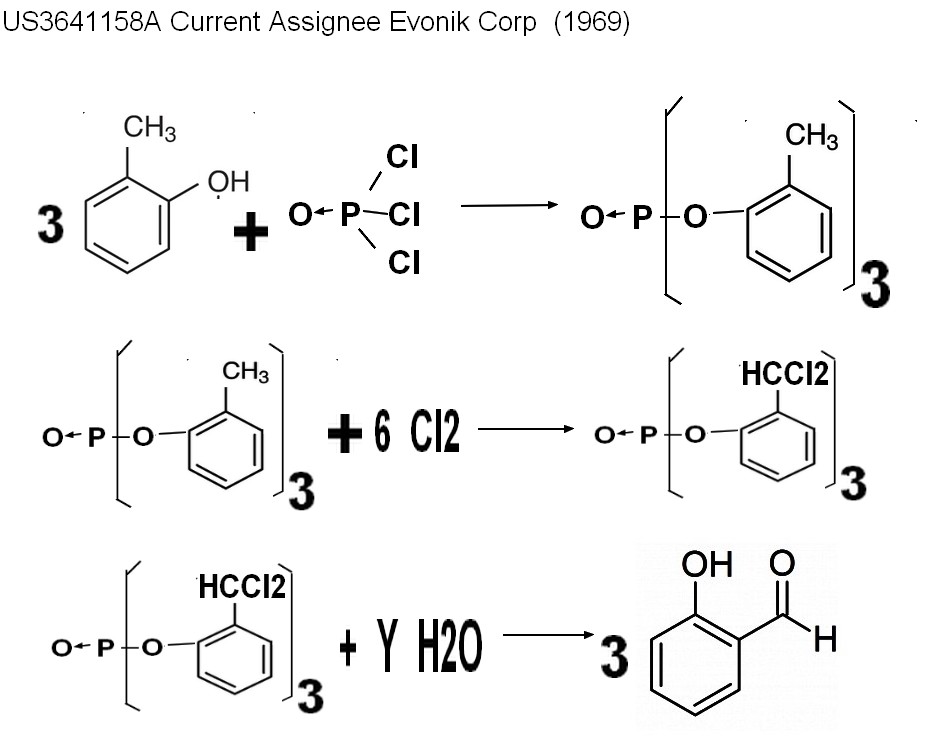

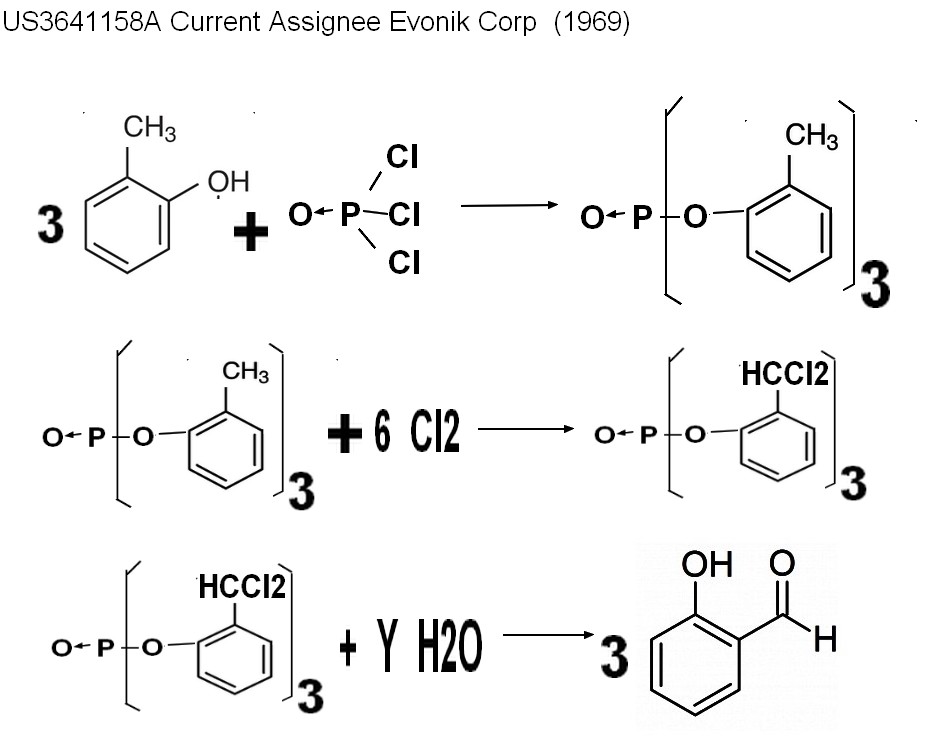

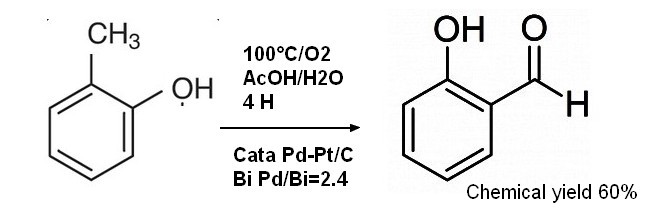

2-3"Ortho cresol" process

Chlorination + hydrolyse

US1023758A Inventor Friedrich Raschig (1909)

US3314998A (1964) Universal Oil Products C

US3641158A Current Assignee Evonik Corp (1969)

US4490559A * 1984-03-27 1984-12-25 Shell Oil Company Process for making aldehydes from diesters of carbonic acid

Example of lab procedureDirect oxydation Industrial chemistry Library vol 8 p 388 (Elsevier)

US5354919(1992)

CA2099681A1·1993-12-30

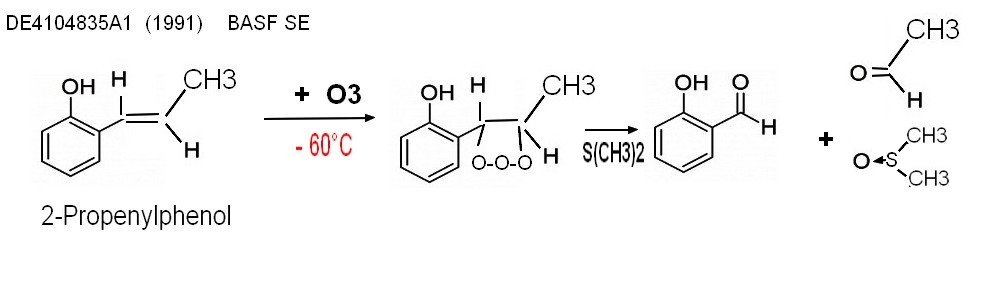

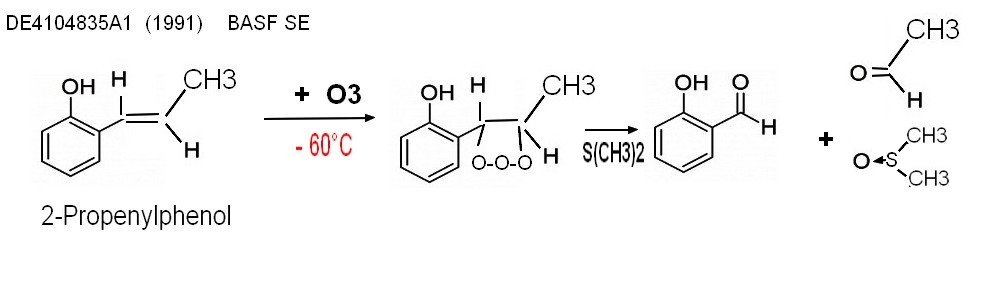

2-4 Miscellaneous processes

2-4 Miscellaneous processes "Ozonolyse process"

DE4104835A1 (1991) BASF SE Salicylaldehyde prodn. - by ozonisation of o-propenyl-phenol

lab procedure

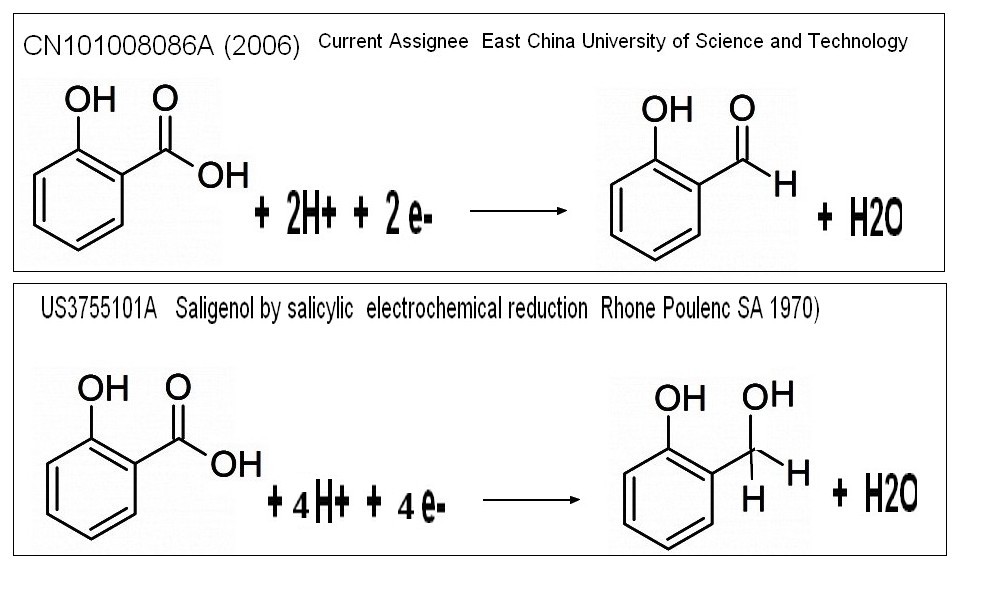

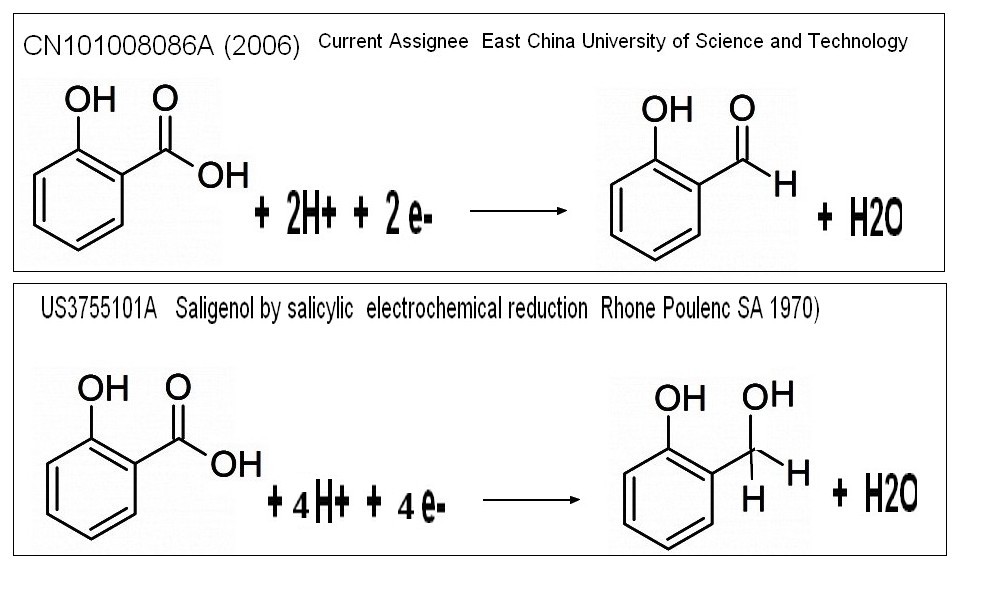

"ELECTRO reduction of salicylic acid "

CN101008086A (2006) Current Assignee East China University of Science and Technology

The invention relates to a direct electro-reduction method for preparing

ortho-hydroxybenzaldehyde with 2-hydroxybenzoic acid in H type

electrolyser, which is characterized in that quaternary ammonium salt

addictive is added in cat electrode room. It takes lead plate as cathode

and anode, takes ortho-hydroxybenzaldehyde and hydric sulphate as

electrolytic solution for cathode and anode, the current efficiency

reach over 35% at 10- 40 Deg. C and current density of 500- 2000 A/ m2,

which is 10% more than that without additive.

As

is the process giving salicylaldehyde cannot compete with chemical processes The main

problem is to prevent further reduction of salicylaldehyde produced

into saligenol .

An older patent claimed more decent chemical yield in saligenol starting from salicylic acid (US3755101A Rhone Poulenc SA 1970)CN101008086 : Lab procedure example

Electro reduction to saligenol : lab procedure

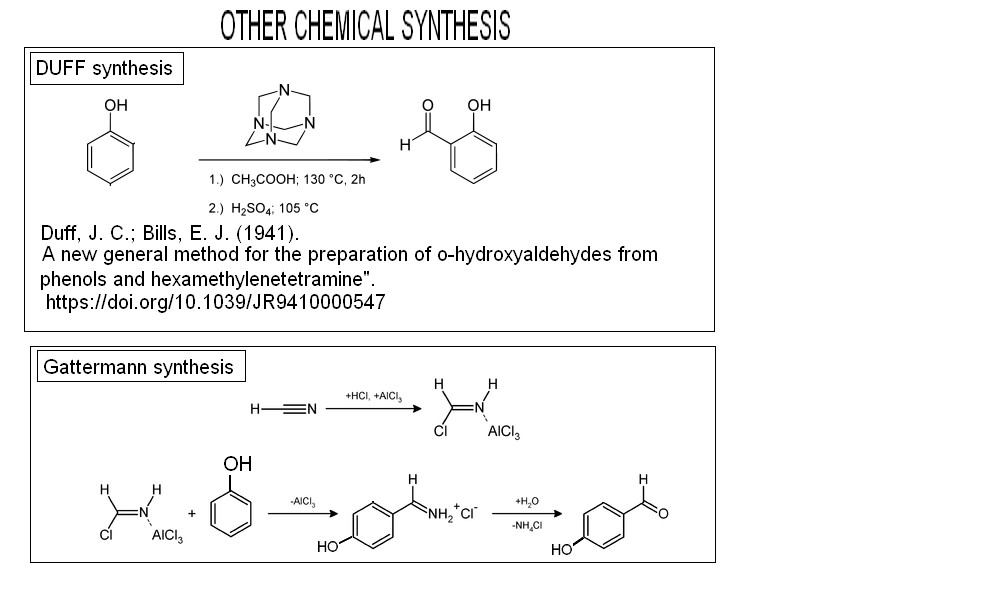

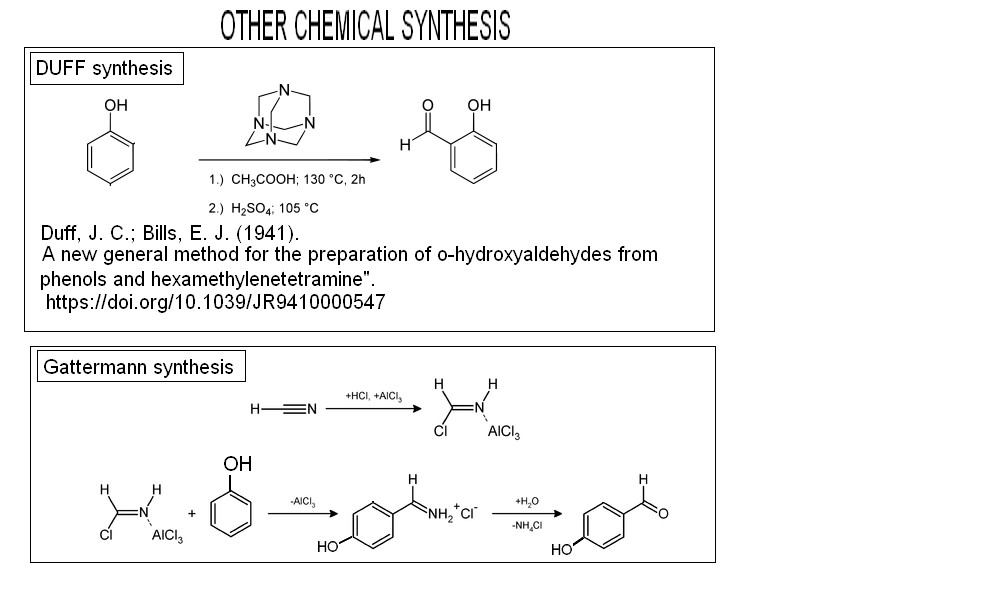

OTHER WELL KNOW PROCESSES to get Hydroxy aldehyde from phenol

***************************************************

More details related to salicylaldhyde patents

More details related to saligenol patents